In the industries that process and recycle metal, cutting scrap metal is an essential step. Two prominent machines often employed for this task are the Alligator Shear and the Gantry Shear. Both machines serve the same purpose of cutting metal but differ significantly in their design, functionality, and the scale of operations they support.

Recognizing the differences between these two machines enables businesses to make a well-informed decision on which one best fits their specific requirements.

This article will provide a detailed comparison of the alligator shear and gantry shear machines, exploring their advantages, disadvantages, and suitability for different operations. Let’s dive into a comprehensive breakdown of these two machines.

Two Metal Shear Machine Comparison Table

| Feature | Alligator Shear | Gantry Shear |

| Size | Compact, ideal for smaller operations | Large, suitable for industrial-scale use |

| Cutting Capacity | Ideal for small-to-medium-sized scrap | Can handle large, bulky scrap materials |

| Power | Moderate hydraulic power | High hydraulic power for heavy-duty cutting |

| Cost | Relatively low-cost, budget-friendly | Higher upfront cost, suited for large operations |

| Efficiency | Quick for small tasks, manual or semi-automated | High efficiency for bulk processing, often automated |

| Maintenance | Low maintenance, easy to repair | High maintenance, requires regular servicing |

| Best For | Small to medium recycling operations | Large scrap yards, recycling plants, steel mills |

| Automation | Rarely automated | Often includes automation features |

Alligator Shear

The Alligator Shear, also known as a crocodile shear, is a hydraulic-powered cutting machine named after its jaw-like design. The machine operates by using a hinged blade mounted on an arm that snaps shut to cut through small-to-medium-sized pieces of scrap metal, such as bars, pipes, or sheets. Alligator shears are ideal for small scrap yards and metal recycling facilities due to their compact size, affordability, and ability to handle a variety of metal types.

Alligator shears are often used to prepare scrap metal for further processing or transportation by cutting it down to smaller sizes. They are adaptable devices that work with both non-ferrous and ferrous metals.

Pros | Cons |

|

|

Gantry Shear

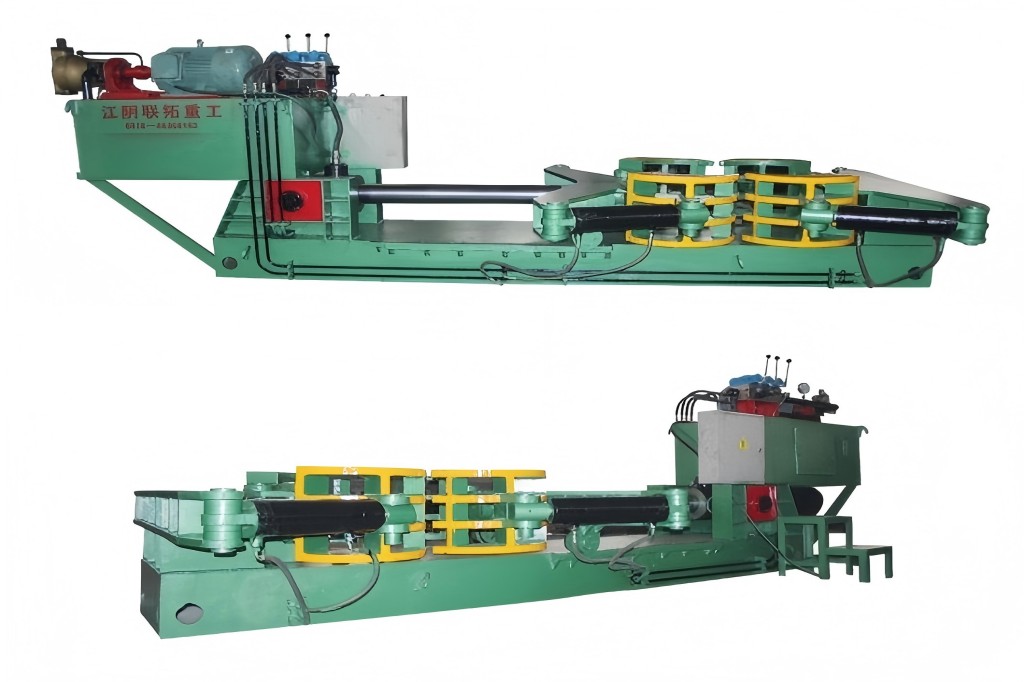

The Gantry Shear is a large, industrial-grade metal cutting machine designed to handle bulky scrap materials in high-volume processing environments. Gantry shears use a stationary gantry frame, through which large pieces of metal are fed for cutting. These machines are equipped with powerful hydraulic systems that generate immense cutting force, enabling them to process large volumes of scrap in one motion.

Gantry shears are widely used in large scrap yards, steel mills, and recycling plants where heavy-duty cutting of oversized scrap metal is required. Due to their size and power, gantry shears are typically equipped with automation features to allow continuous processing and maximize efficiency.

Pros | Cons |

|

|

Which Machine is Right for Your Business?

Choosing between an alligator shear and a gantry shear depends on several factors, including the scale of your operations, the type of metal you process, and your budget.

Choose an Alligator Shear If:

- You manage a recycling facility or scrap yard of small to medium size.

- You primarily process smaller pieces of scrap metal, such as metal bars, pipes, and sheets.

- You require an affordable solution with a low upfront cost.

- Your facility has limited space and cannot fit large equipment.

- You prefer a machine that is simple to maintain and operate.

Alligator shears are ideal for businesses that handle light-to-medium-duty metal-cutting tasks and need a flexible, affordable solution. They are particularly useful for facilities where space is limited, and the volume of scrap metal processed is relatively low.

Choose a Gantry Shear If:

- You operate a large-scale industrial scrap yard or recycling plant.

- You regularly process bulky metal scraps, such as car bodies, steel beams, and large sheets.

- You require a machine with high cutting capacity and heavy-duty performance.

- You are ready to invest substantially in equipment that provides long-term benefits.

- You have the space and resources to maintain a large industrial machine.

Gantry shears are best suited for industrial-scale operations that require continuous processing of large volumes of metal. If your business handles a high volume of scrap metal and needs to cut bulky materials efficiently, a gantry shear is likely the better option.

Conclusion

Both the alligator shear and gantry shear provide substantial benefits in metal processing, but selecting the right one depends on your specific operational requirements.

When deciding which machine to invest in, consider factors such as the volume and type of scrap metal you process, your available space, budget, and long-term operational goals. Both machines have their unique strengths, and choosing the right one can enhance your metal processing efficiency, reduce costs, and improve profitability over time.