Scrap metal recycling is essential for conserving natural resources, reducing landfill waste, and lowering carbon emissions. Choosing the right baler machine is crucial for efficient processing, storage, and transport. Efficient compaction of waste into bales maximizes space utilization, reduces transportation trips, and cuts operational costs.

This article guides businesses in selecting the right scrap metal baler by considering factors like scrap volume, material type, facility space, and the relationship between bale size, compression ratio, and operational efficiency.

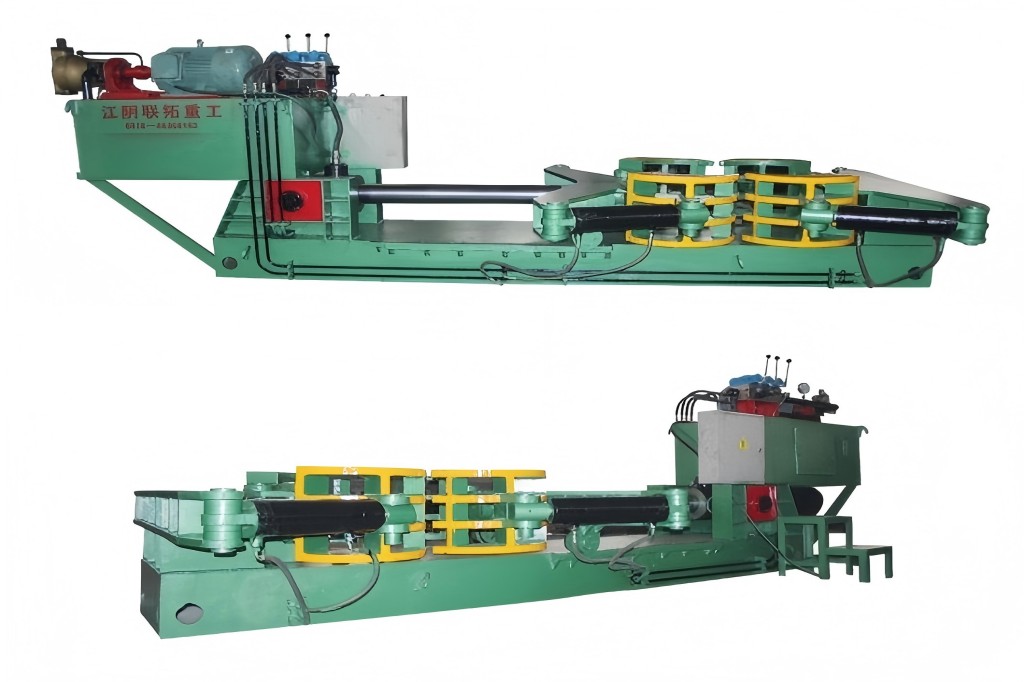

Metal Baler Machine Introduction

A scrap metal baler machine is designed to compact loose metal waste into dense, rectangular bales that are easier to handle, transport, and store. By compacting the metal, these machines significantly decrease its volume, enabling more efficient storage and transport. The compact bales also increase the resale value of recycled metal, as buyers often prefer uniform, manageable sizes for further processing.

Types of Baler Machines

- Vertical Baler Machines: These compact machines are ideal for smaller volumes of scrap metal and facilities with limited space. They are normally operated by hand and are designed for processing smaller amounts of material.

- Horizontal Baler Machines: For larger operations, horizontal balers handle higher volumes and often feature automated processes to boost productivity. They offer higher compression ratios, producing denser bales that optimize storage and transport.

- Auto-tie and Manual-tie Balers: Auto-tie balers automate the tying process for faster production and reduced labor, while manual-tie balers are more affordable but require manual intervention.

Having discussed the various types of balers, let’s now examine how bale size affects logistics and transportation.

Understanding Bale’s Size and Its Impact

Definition of Bale Size

Bale size refers to the dimensions, weight, and density of the compacted metal block produced by the baler machine. Bale size directly affects how much material can be processed at once, how much space the bales take up in storage, and how efficiently they can be transported.

Impact on Logistics and Storage

The size of the bales produced by a baler machine has a significant impact on storage space, transportation efficiency, and overall material handling. Larger, denser bales maximize space in warehouses and shipping containers, reducing the need for frequent transportation and storage reorganization.

Transportation Efficiency

Bigger, more compact bales optimize the use of truck space, allowing for more material to be shipped in fewer trips. This decrease in transportation frequency reduces fuel expenses and lessens the environmental impact tied to scrap metal transport. By selecting the right bale size, businesses can achieve better transportation efficiency and save on logistics expenses.

Selecting Bale Size

The ideal bale size depends on the type of metal being processed and the specific needs of the recycling facility. For instance, smaller bales might be preferable for light metals such as aluminum, which are easier to handle, while larger bales are better suited for dense metals like steel and copper. Facilities with limited space may prioritize smaller bales, while those focused on maximizing transport efficiency will likely opt for larger sizes.

The Role and Significance of Compression Ratios

Definition of Compression Ratio

The compression ratio reflects the degree to which a baler machine can compress scrap metal. It represents the ratio of the uncompressed volume to the volume of the compressed bale. A higher compression ratio indicates that the material is being compacted more tightly, resulting in denser bales.

Impact on Bale Density

Bales with higher compression ratios are denser, which can lead to significant cost savings. Denser bales take up less space in storage and transport, enabling a more efficient use of resources. Additionally, denser bales often fetch higher prices in the recycling market, as they are easier to handle and process further.

Compression Ratio Variations

Different baler machines offer varying compression ratios depending on their size, type, and design. Horizontal balers, for instance, tend to provide higher compression ratios than vertical balers, making them ideal for large-scale operations that require highly compacted bales. The type of metal being processed also affects the compression ratio, as denser metals like steel and copper require greater compression force than lighter materials such as aluminum.

Efficiency and Productivity

Compression ratios are directly linked to the productivity of recycling facilities. Machines with higher compression ratios produce more compact bales, which reduces the time and effort needed for handling, transportation, and storage. This results in greater operational efficiency and higher throughput.

Comprehensive Quantitative Data Table

To provide a clearer comparison of the performance metrics of different baler machines, here’s a detailed table of data showing how each machine type performs across key metrics such as bale size, compression ratio, operational pressure, and power consumption:

| Baler Type | Bale Size (L x W x H in mm) | Compression Ratio | Bale Weight (kg) | Throughput (tons/hour) | Operational Pressure (tons) | Power Consumption (kW) | Suitable Materials |

| Vertical Baler | 600 x 800 x 1000 | 3:1 to 5:1 | 50 – 300 | 0.5 – 1.5 | 20 – 30 | 10 – 15 | Aluminum, cardboard, light steel |

| Horizontal Baler | 1100 x 1100 x 1500 | 8:1 to 10:1 | 400 – 600 | 3 – 5 | 50 – 100 | 20 – 25 | Copper, steel, aluminum |

| Auto-tie Baler | 1200 x 1200 x 1600 | 10:1 to 12:1 | 500 – 800 | 5 – 7 | 100 – 150 | 30 – 40 | High-density steel, copper |

| Manual-tie Baler | 800 x 1100 x 1300 | 5:1 to 8:1 | 300 – 500 | 2 – 4 | 40 – 60 | 15 – 20 | Mixed metals, aluminum |

Important Factors to Evaluate When Choosing a Scrap Metal Baler Machine

Material Type

Different metals, such as ferrous (iron and steel) and non-ferrous (aluminum, copper, brass), have varying compaction properties, which influence the required compression ratio and bale size. Non-ferrous metals, being lighter, may not require as high a compression ratio as ferrous metals, which are denser and more difficult to compact.

Processing Volume

The volume of material processed daily or weekly is a critical factor in choosing the right baler machine. High-volume operations require larger balers with greater compression capabilities, while low-volume facilities may find smaller balers more cost-effective.

Facility Space and Layout

The available space in the recycling facility will dictate the size and type of baler machine that can be installed. Vertical balers are perfect for facilities with space constraints, whereas horizontal balers, although larger, provide higher processing capacity and compression ratios. Additionally, the layout of the facility should accommodate the machine’s operation, material flow, and storage needs.

Handling and Bale Weight

The weight of the bales is an important consideration, especially for transportation and handling. Heavy bales may require specialized equipment such as forklifts or cranes, while lighter bales can be moved manually or with basic equipment. Businesses should make certain they have the proper handling equipment for the bales their machine produces.

Automation and Technology

Modern baler machines come equipped with advanced features such as automatic bale ejection, pressure control, and energy efficiency settings. These features help reduce labor costs, increase operational efficiency, and ensure consistent bale size and compression. Automation is particularly valuable for high-volume operations that require continuous processing without downtime.

Matching Bale Size and Compression Ratio to Operational Requirements

Optimizing for Business Needs

Businesses must evaluate their specific recycling needs to select the right combination of bale size and compression ratio. This can depend on factors such as the type of material processed, the facility’s available space, and the desired output. A decision matrix that takes these factors into account can assist businesses in making a well-informed decision.

The Role of Automation in Baler Selection

Automated balers deliver key benefits in terms of speed, efficiency, and reducing labor costs. They are well-suited for businesses aiming to sustain consistent output while minimizing the need for manual oversight. Automation ensures that bale size and compression ratio are optimized for every batch, leading to higher productivity and cost savings.

Regulatory and Environmental Considerations

Scrap metal recycling is governed by several regulations designed to reduce environmental impact and promote safe, efficient operations. Baler machines that produce compact bales help businesses meet these regulatory standards by reducing transportation emissions and optimizing recycling efficiency. Additionally, compliance with environmental standards often translates into financial incentives or tax breaks for recycling facilities.

Conclusion

Selecting the right scrap metal baler machine is essential for optimizing recycling operations. By thoroughly assessing bale size and compression ratio, businesses can boost efficiency, cut costs, and lessen their environmental impact.

The right baler machine ensures that scrap metal is processed, stored, and transported in the most efficient manner possible, contributing to both profitability and sustainability. To make the most of your recycling operations, carefully assess your needs and consult with our team for expert guidance on selecting the best baler solution for your business.