In the world of industrial manufacturing, the gantry shear machine has become a staple for cutting large metal sheets and plates with precision and efficiency. Known for their ability to handle thick materials and heavy-duty cutting tasks, gantry shear machines are widely used in industries like automotive, shipbuilding, aerospace, construction, and metal recycling.

Gantry shear machines do have certain benefits and drawbacks, just like any large piece of industrial machinery. This article will provide a detailed look at the pros and cons of gantry shear machines, helping businesses better understand their capabilities and limitations.

What is a Gantry Shear Machine?

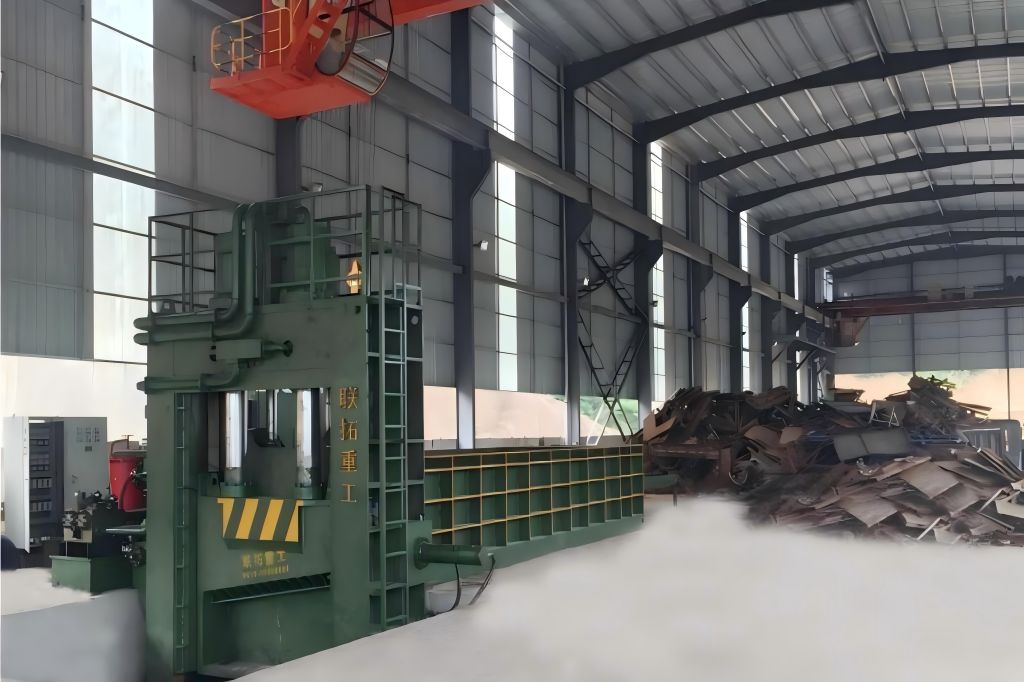

A gantry shear machine is a type of industrial shear used primarily for cutting large sheets of metal. Its design features a horizontal beam, or gantry, which moves along tracks above the metal sheet. The gantry supports a shearing blade that moves downward vertically to slice through the metal. The machine is powered by hydraulics or mechanical systems that provide the force necessary to cut through thick metal materials like steel, aluminum, and other industrial-grade alloys.

These machines are engineered for large-scale metal processing, providing both versatility and increased productivity. Their capacity to manage heavy-duty tasks has made them crucial tools across multiple industries.

Pros of Gantry Shear Machines

1. Precision and Accuracy

A key advantage of gantry shear machines is their capability to cut materials with exceptional precision. The gantry structure allows for a stable cutting process, ensuring minimal deviation from the intended cut line. This level of accuracy is crucial in industries like aerospace, automotive, and shipbuilding, where even the slightest error in metal cutting can result in costly delays or failures in product assembly.

The ability to make precise cuts also reduces material waste, which is another significant benefit. By cutting accurately, manufacturers can optimize material usage, thereby reducing scrap and lowering costs. In addition, precise cuts eliminate the need for extensive finishing processes, further increasing overall production efficiency.

2. Handling Large, Thick Materials

Industries that deal with heavy-duty materials, such as shipbuilding and metal recycling, benefit greatly from the capability of gantry shear machines to handle metal plates that are several inches thick. Unlike smaller, conventional cutting machines, gantry shears are designed to cut through such thick metal sheets without compromising on precision. For industries that frequently produce large metal plates, this function is especially helpful.

3. Durability and Longevity

Built for industrial applications, gantry shear machines are incredibly durable. They are made of sturdy materials and made to survive hard working conditions, such as exposure to high pressure, vibration, and wear. This durability translates into longer machine life and reduced downtime due to maintenance or repairs, making gantry shear machines a cost-effective investment for many businesses.

4. Versatility Across Industries

Gantry shear machines are not limited to cutting only one type of material or being used in a single industry. They can handle many different kinds of metals, such as titanium, steel, aluminum, and more, because of their adaptability. This makes them applicable in diverse fields such as automotive manufacturing, shipbuilding, construction, and scrap metal recycling. Furthermore, the gantry design makes it easier to cut metal sheets of different sizes and thicknesses, offering businesses flexibility in their operations.

Moreover, with the ability to accommodate both lightweight alloys and heavy-duty metals, gantry shear machines provide a range of cutting options, allowing manufacturers to meet the specific demands of each industry.

5. Increased Efficiency

Efficiency is a critical factor in industrial production, and gantry shear machines contribute significantly in this regard. These machines can process large quantities of metal sheets quickly, making them an ideal choice for businesses that need to maintain high production rates. The combination of speed and accuracy helps streamline production lines, reducing manual labor and the need for secondary processes like grinding or finishing.

For instance, in automotive manufacturing, where body panels, chassis parts, and other components are needed in large volumes, gantry shears enable fast, precise cutting, minimizing material wastage and reducing production delays.

6. Automation Capabilities

Modern gantry shear machines come equipped with advanced automation features that allow operators to program and control the machine for different cutting tasks. These machines’ ability to execute intricate cutting jobs with little assistance from humans thanks to CNC (computer numerical control) capabilities increases overall efficiency and lowers the risk of human error. This level of automation also enhances safety, as workers are less exposed to potential hazards during the cutting process.

Cons of Gantry Shear Machines

1. High Initial Investment Cost

One of the primary drawbacks of gantry shear machines is their high initial cost. These machines require significant capital investment, particularly for large models with advanced features such as CNC automation. This initial investment may be a deterrent for small and medium-sized enterprises. However, the long-term advantages frequently outweigh the upfront costs for businesses with huge production volumes and specialized cutting requirements.

Additionally, businesses must consider not only the cost of purchasing the machine but also the expenses related to installation, training, and periodic maintenance. To justify the investment, businesses must assess their production volumes and material processing needs, ensuring that the machine’s capacity aligns with their long-term operational goals.

2. Maintenance and Repair Costs

While gantry shear machines are built to be durable, they require regular maintenance to ensure optimal performance. Components such as the hydraulic systems, blades, and motors can wear out over time, necessitating repairs or replacements. These upkeep duties can get costly, particularly if specialist components or personnel are needed. Moreover, downtime for repairs can disrupt production schedules, potentially leading to delays.

For businesses that rely heavily on these machines, it is crucial to have a solid maintenance plan in place to minimize downtime and extend the lifespan of the equipment. Investing in preventive maintenance can help mitigate the impact of costly repairs and keep the machine running efficiently.

3. Size and Space Requirements

Gantry shear machines are large, heavy pieces of equipment that require significant space for both operation and installation. This might be problematic for companies with small floor plans. The gantry structure, along with the metal sheets being processed, demands ample room for safe operation. Businesses may occasionally need to make greater facility investments or rearrange their current factory floor to make room for these devices.

The size of gantry shears also makes transportation and installation more complicated, adding to the overall setup cost. It is important for companies to evaluate their facility’s layout and space before purchasing a gantry shear machine, to ensure it can be integrated smoothly into existing operations.

4. Complex Operation and Training

Operating a gantry shear machine requires technical knowledge and experience. While modern machines come equipped with CNC automation, operators still need to understand the intricacies of programming, troubleshooting, and performing basic maintenance tasks. In order to guarantee that operators can operate the machine safely and effectively, businesses must spend on employee training.

The learning curve for mastering gantry shear operation can be steep, especially for companies transitioning from manual or less complex cutting systems. Proper training is essential to prevent accidents and ensure optimal machine performance. Companies should think about continuing training initiatives to keep operators informed about new safety regulations and technological advancements.

5. Energy Consumption

Gantry shear machines, particularly hydraulic models, consume significant amounts of energy during operation. This can lead to higher energy costs, especially for businesses that use the machine for extended periods or in high-volume production environments. The energy requirements for powering the hydraulics, motors, and CNC systems can contribute to the overall operating expenses of the machine.

Nevertheless, some more recent models are made to use less energy due to developments in energy-efficient technologies, which will ultimately make them more economical and sustainable.

Is a Gantry Shear Machine Suitable for Your Business?

Gantry shear machines offer a host of benefits, making them invaluable tools in industries that require high-precision, large-scale metal cutting. Their ability to handle thick materials, provide accurate cuts, and operate with high efficiency has made them an essential part of the manufacturing process in sectors such as automotive, shipbuilding, and aerospace. They can also be utilized in a variety of applications due to their adaptability, such as cutting components for infrastructure projects or recycling scrap metal.

However, businesses must carefully evaluate factors such as production volumes, material types, space requirements, and potential ROI (Return on Investment) before making such a significant purchase. With proper planning, training, and maintenance, the long-term benefits of these machines can far exceed the challenges, making them a valuable addition to any production facility focused on high-volume metal cutting.