As global concerns about waste generation and environmental sustainability escalate, the importance of effective recycling systems has never been more significant. Metal balers have emerged as essential tools for recycling facilities, manufacturers, and scrap yards, enabling efficient processing of metal waste.

This comprehensive buying guide explores the top five metal balers of 2024, equipping you with the knowledge to make an informed purchasing decision tailored to your operational needs.

Understanding Metal Balers

What is a Metal Baler?

Metal balers are specialized equipment made to compact metal scrap into small bales for simpler handling, storage, and transportation. These devices are essential to the recycling process because they turn loose metal debris into units that are easier to handle. By reducing the volume of scrap metal, balers enhance logistical efficiency and decrease disposal costs.

Why Invest in a Quality Metal Baler?

Investing in a high-quality metal baler offers numerous advantages:

- Efficiency: Advanced balers can process large quantities of metal quickly, significantly reducing turnaround times in recycling operations.

- Cost Savings: Minimizing waste volume helps businesses cut transportation and disposal fees.

- Safety: Automated systems decrease reliance on manual handling, thereby improving workplace safety.

- Environmental Benefits: Reducing the carbon footprint connected with metal production and conserving natural resources are two benefits of efficient recycling operations.

1. Harris 50R Baler

Overview: The Harris 50R is a standout in the metal baler market, renowned for its robust construction and high efficiency. Suitable for various metals, including aluminum, steel, and copper, this model is designed to meet the demands of medium to large recycling operations.

Key Features:

- Compression Force: 50 tons, ensuring powerful compaction for a variety of metal types.

- Bale Size: Adjustable bale sizes (up to 60”x30”x30”), allowing flexibility based on operational needs.

- Automation: Fully automated operation, reducing labor costs and improving efficiency.

- Durability: Built with sturdy steel for extended use in challenging conditions.

Performance and Efficiency: The Harris 50R can process up to 15 tons of metal per hour, making it an efficient choice for busy recycling facilities. Operators can effortlessly monitor performance thanks to its user-friendly UI.

2. Bramidan B4 Baler

Overview: The Bramidan B4 baler is compact yet powerful, ideal for smaller recycling operations that require efficient processing of metal scrap. Its compact design allows it to function well even in small spaces while preserving great performance.

Key Features:

- Compression Force: 35 tons, which effectively compacts a range of materials.

- Footprint: Small footprint (only 48″ by 42″) makes it simple to integrate into constrained areas.

- Manual/Automatic Control: Operators can choose between manual operation or automatic cycle control for enhanced convenience.

Performance and Efficiency: The Bramidan B4 can produce bales weighing up to 800 pounds, efficiently processing up to 8 tons of metal per hour.It’s a popular option for smaller scrap yards because of its adaptability.

3. Metso N Series Baler

Overview: Metso’s N Series balers are known for their advanced technology and reliability, suitable for large-scale operations. They are designed for maximum efficiency in processing heavy metal scrap.

Key Features:

- Compression Force: Up to 120 tons, capable of handling the toughest metal materials.

- Tailored Options: Different chamber sizes and bale weights can be adjusted to fit specific operational needs.

- Smart Control System: Equipped with a sophisticated programmable logic control system for accurate operation and monitoring.

- Energy Savings: Engineered to minimize energy use while delivering optimal performance.

Performance and Efficiency: The Metso N Series can process over 20 tons of metal per hour, making it one of the most efficient models available. Even with constant use, its sturdy build guarantees longevity.

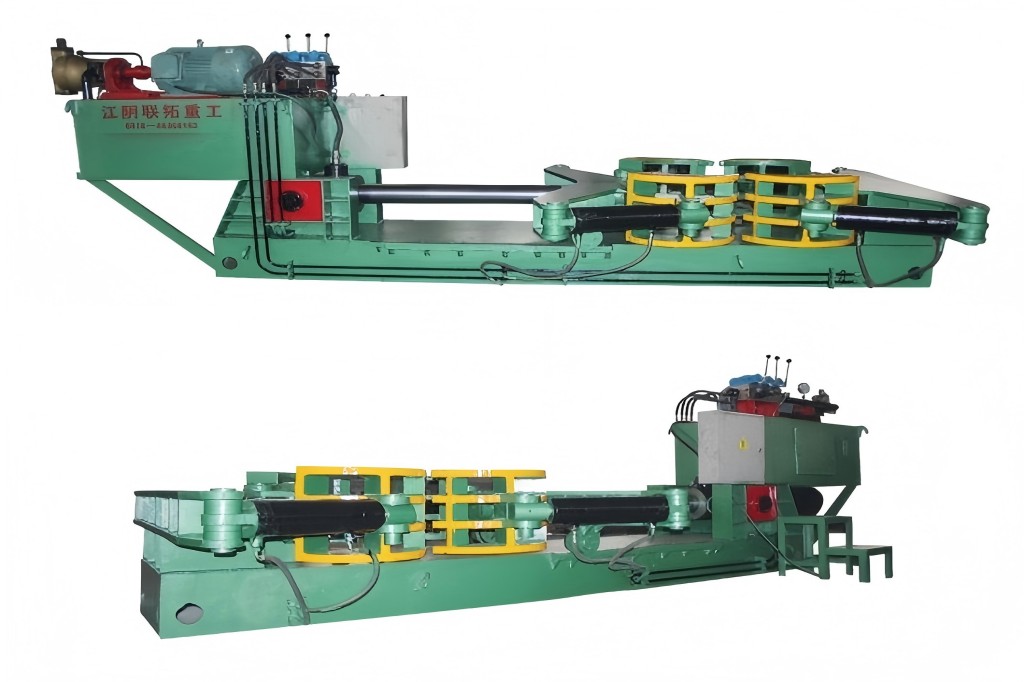

4. Unite Top Y81 Series Metal Baler

Overview: The Unite Top Y81 Series Metal Baler is a versatile option for various recycling operations, featuring advanced hydraulic technology and customizable options to meet specific needs.

Key Features:

- Hydraulic Drive Models: Ensures powerful and efficient operation.

- Discharging Options: Four bale discharging options to suit different processing requirements.

- Pressure Range: Extrusion pressure from 63 to 2000 tons, making it suitable for a wide range of materials.

- Production Efficiency: Capable of processing 0.5 to 20 tons per hour, with customizable chamber and bale sizes.

Performance and Efficiency: Scrap metal recyclers choose the Y81 Series because of its reputation for dependable performance and versatility.

5. Sinobaler Vertical Metal Baler

Overview: Sinobaler’s Vertical Metal Baler is engineered for efficiency and reliability, making it an excellent choice for recycling operations of various sizes.

Key Features:

- Compression Force: Up to 100 tons, capable of handling different types of metal scrap.

- Bale Size Customization: Offers customizable bale sizes to meet specific recycling requirements.

- Energy-Saving Design: made with the goal of maximizing production and reducing energy use.

- Simple to Use: An intuitive interface makes monitoring and operation a breeze.

Performance and Efficiency: This baler can handle approximately 10 tons of metal per hour, making it suitable for both small and medium-sized operations.

Considerations for Purchasing a Metal Baler

Capacity Needs

Evaluate your recycling operation’s volume and type of materials processed. Ensure that the baler you choose can handle your current and projected workloads efficiently.

Space Restrictions

Consider the available space in your facility. Compact balers may be necessary for smaller operations, while larger facilities can accommodate more heavy-duty models.

Automation Features

To increase efficiency and save labor expenses, look for balers that have automated possibilities. Automated controls can make the operation easier and more efficient.

Maintenance

Recognize the baler’s maintenance requirements. Models that offer easy access for repairs and routine checks can save time and reduce downtime.

Cost

Consider your budget and weigh it against the features offered by different balers. While investing in a high-quality baler may be more expensive initially, it can lead to significant long-term savings.

Conclusion

Investing in a metal baler is a strategic decision that can greatly enhance your recycling operations. When choosing the right baler, carefully assess your specific requirements, including capacity, bale size, automation features, and energy efficiency. By making an informed decision, you can significantly improve your metal recycling process, reduce costs, and contribute to a more sustainable future.