The cardboard baler machine is an important piece of equipment for compacting and recycling cardboard waste, and the prices of various packaging machines with different functions vary greatly. Differences in type, size, capacity, function, and manufacturer brand cause this variability.

This guide outlines the main factors that affect the cost of bundling machines and emphasizes the importance of considering these aspects when purchasing to ensure effective waste management within budget constraints.

Types of Cardboard Balers

Cardboard balers come in several designs, each tailored to meet different operational needs and budget considerations. The main types include:1. Vertical Balers

The most common and cost-effective option, suitable for small to medium volumes of cardboard waste. They require manual feeding and removal of bales but are compact and easy to operate, making them ideal for businesses with limited space and lower volume recycling needs.2. Horizontal Balers

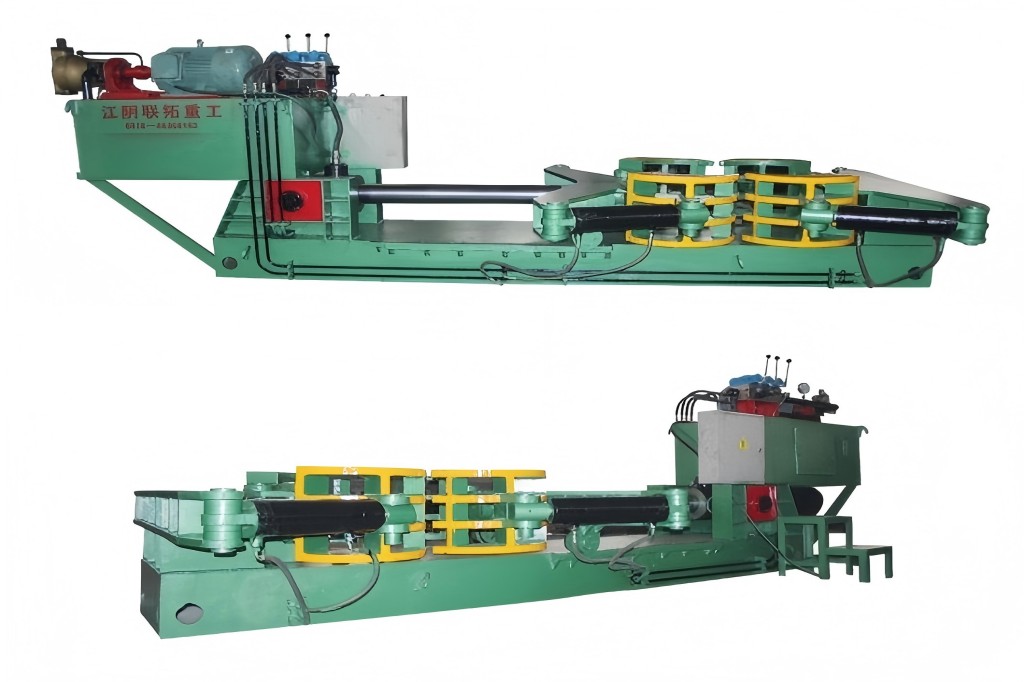

Designed for high-volume waste processing, these balers automatically compress and eject bales. They are more expensive than vertical packaging machines, but more efficient for large operations such as recycling centers and large retail stores.3. Automatic Balers

These balers automate the entire baling process, from feeding to bale tying, significantly reducing labor costs. Ideal for operations with continuous, high-volume recycling needs, they represent a higher upfront investment but offer savings in labor and time.4. Semi-Automatic Balers

A middle ground between manual and fully automatic options, semi-automatic balers may require manual tying of bales or some form of manual operation. They offer a balance of cost savings and operational efficiency.Size and Capacity

The size and capacity of a cardboard baler are critical factors that significantly influence its price. Balers are designed to accommodate varying volumes of waste, and selecting the right size and capacity is essential for operational efficiency and cost-effectiveness.1. Small Balers

Ideal for businesses with limited space and lower volumes of cardboard waste. These balers are the most affordable, and suitable for small retail stores, offices, or restaurants. Their compact size allows for easy placement, but they have a lower throughput and smaller bale size.2. Medium Balers

These are a step up in both size and capacity, designed for businesses with moderate recycling needs. Medium balers offer a good balance between price and performance, capable of handling larger volumes of waste without occupying as much space as the larger models.3. Large Balers

Built for high-volume waste producers like manufacturing plants, large retail operations, and recycling centers. Large balers have the highest price tags but are the most efficient for processing substantial amounts of cardboard. They produce larger bales, require more space, and have higher operational costs but provide significant long-term savings in waste management and recycling.Features and Specifications

The features and specifications of a cardboard baler can vary greatly, affecting both its utility and price. Understanding these can help in choosing a baler that not only fits within your budget but also meets your operational needs efficiently.1. Bale Size and Weight

Balers can produce bales of varying sizes and weights, impacting how easily they can be handled, stored, or transported. Larger, heavier bales may reduce the frequency of disposal but require more space and possibly heavier machinery for handling.2. Cycle Time

This refers to how quickly a baler can process material and produce a bale. Shorter cycle times mean higher efficiency and throughput, which is crucial for operations with high volumes of cardboard waste. However, faster balers can also be more expensive.3. Operation Mode

Balers can be manual, semi-automatic, or fully automatic. Manual balers are the least expensive but require more labor. Fully automatic balers, while costing more upfront, can save significant labor costs over time by automating the baling process.4. Safety Features

Advanced safety features such as emergency stop buttons, safety gates, and automatic shutdown can add to the cost of a baler but are essential for protecting operators from accidents.5. Energy Efficiency

Some balers are designed to be more energy-efficient than others, reducing operational costs over time. While these models might have a higher initial price, the long-term savings on electricity can be considerable.6. Durability and Maintenance Requirements

The build quality of a baler affects its durability and the frequency of maintenance needed. Higher-quality materials may increase the purchase price but can lead to lower maintenance costs and longer service life.7. Additional Features

Features like integrated scales for weighing bales, wireless monitoring capabilities, and automatic wire-tying mechanisms can enhance the convenience and efficiency of a baler but will also impact the price.Brand and Manufacturer

The choice of brand and manufacturer plays a significant role in determining the cost, quality, and reliability of a cardboard baler. Each brand comes with its reputation for durability, customer service, and after-sales support, all of which can influence the purchasing decision and the total cost of ownership.1. Reputation and Reliability

Established brands with a proven track record in manufacturing reliable balers might command higher prices. However, the investment in a well-known brand can often translate to fewer breakdowns, lower maintenance costs, and longer equipment life.2. Customer Service and Support

Manufacturers known for excellent customer service and after-sales support offer added value. This includes access to technical support, availability of spare parts, and warranty conditions. The benefits of prompt and effective service can offset a higher initial cost.3. Warranty and After-sales Service

The length and coverage of the warranty are important considerations. A comprehensive warranty can save significant money in repair or replacement costs. Evaluate the manufacturer’s after-sales service options, as ongoing support and maintenance are crucial for the baler’s longevity and performance.4. Innovation and Technology

Manufacturers that invest in research and development to incorporate the latest technology and features into their balers may offer products at a premium. These innovations can lead to greater efficiency, safety, and user-friendliness, potentially providing a better return on investment over time.5. Local vs. International Brands

Local manufacturers may offer competitive prices and the advantage of quicker service response times. In contrast, international brands might provide access to more advanced technology and a broader range of products but could come with higher costs and potential challenges in service and support due to geographical distances.6. Customization Options

Some manufacturers offer customization options to tailor the baler to specific operational needs. While this can increase the purchase price, customized features can enhance operational efficiency and ensure the baler meets your exact requirements.New vs. Used Cardboard Balers

When purchasing a cardboard baler, deciding between a new or used model is a significant consideration that impacts both the upfront cost and long-term value. Each choice has its advantages and disadvantages, depending on your budget, operational requirements, and preference for reliability and technology.New Cardboard Balers

Advantages:

- Latest Technology: New balers incorporate the latest advancements in technology, offering improved efficiency, safety features, and operational convenience.

- Warranty Coverage: Comes with manufacturer’s warranty, protecting against defects and malfunctions, which can save on repair costs.

- Lower Maintenance Costs: Being brand new, these machines are less likely to require repairs in the short to medium term, leading to lower maintenance costs.

- Customization: Offers the option to customize according to specific needs, ensuring the baler fits perfectly with your operational requirements.

Disadvantages:

- Higher Initial Cost: The most significant drawback is the higher purchase price compared to used models.

Used Cardboard Balers

Advantages:

- Lower Purchase Price: The most apparent advantage is the cost savings on the purchase price, making it an attractive option for businesses with limited budgets.

- Immediate Availability: Used balers are often available for immediate purchase and delivery, unlike new models, which may require a waiting period for manufacturing and delivery.

- Eco-Friendly Option: Buying used is a form of recycling, contributing to environmental sustainability by extending the life of existing machines.

Disadvantages:

- Potential for Higher Maintenance Costs: Older models may require more frequent repairs and maintenance, potentially increasing long-term operational costs.

- Limited Warranty: Used balers may come with limited or no warranty, posing a risk if the machine breaks down or requires significant repairs.

- Unknown Usage History: There may be uncertainties regarding the baler’s previous usage, maintenance history, and overall condition.