As businesses strive to minimize their environmental footprint, metal balers are proving to be crucial tools in promoting more sustainable practices. Metal balers, a crucial piece of equipment for this sector, condense and compress a variety of scrap metal kinds into dense, manageable bales.

In this article, we will explore metal balers in-depth, covering their working principles, types, benefits, materials handled, maintenance, and key factors to consider when selecting a metal baler.

What is a Metal Baler?

An industrial piece of machinery called a metal baler is used to compress scrap metal into bales. These machines work by applying tremendous force to metal scraps, reducing their volume and making them easier to store, transport, and recycle. Metal balers are available in a range of sizes, shapes, and capacities to accommodate a variety of uses.

Working Principle

The working principle of a metal baler revolves around hydraulic or mechanical force. Scrap metal is fed into a chamber, where it is compressed using one or more powerful hydraulic rams (cylinders that generate pressure) or mechanical presses. The compressive force reduces the metal’s volume, shaping it into a dense, compact form that can be tied off and stacked efficiently. This process not only saves space but also reduces the transportation cost of scrap metal by increasing its weight-to-volume ratio.

Importance in Recycling

Through its ability to handle, store, and transport scrap metal more easily, metal balers are vital to the recycling process. Metal balers reduce scrap volume, allowing recyclers to store and ship larger quantities. This leads to lower logistics costs and less environmental impact.

Additionally, compact bales are easier to melt down in recycling furnaces, leading to energy savings during the recycling process. Overall, metal balers contribute to the circular economy by enabling the efficient reuse of valuable metals, thus minimizing waste and preserving natural resources.

Benefits of Using a Metal Baler

Metal balers offer numerous advantages to businesses involved in metal recycling and waste management. Here are the key benefits:

- Space Saving: By compacting scrap metal into smaller bales, metal balers significantly reduce the amount of space required for storage. This enables companies to manage greater volumes of scrap and make better use of the space that they have available.

- Environmental Impact: By permitting more effective recycling, metal balers help to maintain a sustainable environment. Compacting metal reduces the carbon footprint associated with transportation and processing. Recycling metal also helps to preserve natural resources by lowering the need to mine new materials.

- Cost-Effectiveness: Compressing scrap metal into bales minimizes logistical costs as more material can be transported in a single trip. This cost efficiency extends to recycling plants as well, where compacted metal bales require less energy and processing time during recycling.

- Improved Safety: Handling loose scrap metal can be hazardous, as it may have sharp edges or awkward shapes.

- Increased Efficiency: Metal balers speed up the recycling process by organizing scrap into uniform bales, which are easier to handle, process, and sell. Recycling companies may see an improvement in profitability and production as a result of this enhanced efficiency.

Now that we’ve explored the advantages of metal balers, let’s take a closer look at the different types available.

Principal Types of Metal Balers

Metal balers are made of different kinds, each intended for use with particular materials and purposes. It is essential to comprehend the benefits and drawbacks of each machine before selecting one for your recycling or waste management requirements. The primary categories are listed below:

1. Horizontal Metal Balers

Horizontal metal balers compress scrap metal horizontally, ideal for large recycling facilities. They offer high throughput, and automatic feeding, and can handle various materials. These balers produce dense, uniform bales, optimizing storage and shipping space, and making them perfect for high-volume, continuous operations.

|

Pros |

Cons |

|

|

2. Vertical Metal Balers

Vertical metal balers compress scrap vertically, which is suitable for small to medium facilities with limited space. They are affordable, simple to use, and need little upkeep. Vertical balers handle a range of materials, making them an efficient choice for businesses processing moderate scrap volumes.

|

Pros |

Cons |

|

|

3. Shear Balers

Shear balers combine shearing and baling functions, cutting large metal pieces before compressing them into bales. Designed for heavy-duty applications like vehicle bodies and construction materials, shear balers enhance efficiency by handling oversized scrap and reducing material size for easier processing.

|

Pros |

Cons |

|

|

4 .Mobile Metal Balers

Mobile metal balers, including car compactors, are portable and designed for on-site scrap processing at construction or demolition sites. These machines offer flexibility, allowing businesses to bale scrap metal, including entire vehicles, directly at the source, reducing transportation costs and improving operational efficiency in remote or temporary locations.

|

Pros |

Cons |

|

|

5. Closed-Door Metal Balers

Closed-door metal balers feature an enclosed chamber that produces high-density bales for heavy or valuable metals like steel and copper. They ensure precise control, delivering consistent, uniform bales ideal for industries requiring maximum compression and efficient storage or transportation.

|

Pros |

Cons |

|

|

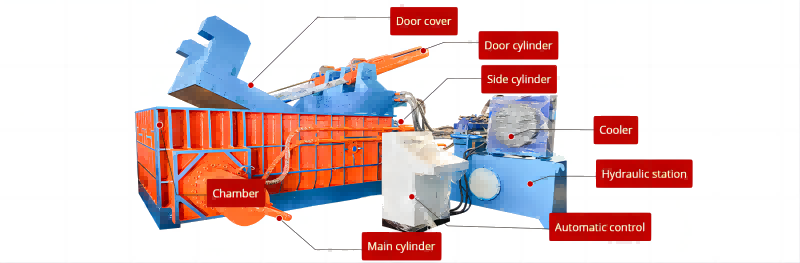

Baler Parts and Accessories

Metal balers are complex machines consisting of various components that work together to compress scrap metal effectively. Here are the key parts and accessories of a typical metal baler:

Main Frame and Housing

The main frame is the structural backbone of a metal baler machine, constructed from heavy-duty steel. It ensures that the machine can endure the high pressure required for compressing metal and serves as the base for all other parts. The housing protects internal components and keeps the machine’s operations safe and secure.

Hydraulic System

The hydraulic system is the baler’s main engine, producing the enormous force needed to compress and bale metal. Important parts of the hydraulic system consist of:

Hydraulic Pump

Transforms mechanical power into hydraulic force, powering the baling operation.

Cylinders

Apply pressure to compress the metal into a compact form.

Valves and Pipes

Direct the flow of hydraulic fluid, ensuring precise operation and control.

Control Panel

Serving as the brain of the metal baler, the control panel enables operators to control the machine’s operations, modify settings, and oversee its performance. Modern balers often feature digital displays and programmable logic controllers (PLCs), which allow for enhanced automation and precision.

Feeding Hopper

Scrap metal is loaded into the machine through the feeding hopper, which can be fed manually or automatically, depending on the machine’s design. In larger operations, conveyor systems are often used to continuously feed material into the hopper.

Compression Chamber

The magic happens in the compression chamber. Scrap metal is compressed under high pressure to form dense bales. The chamber’s walls are designed to withstand extreme forces, and they are often equipped with wear-resistant linings to extend the machine’s lifespan.

Baling Chamber and Bale Ejector

After the metal is compressed, it is transferred to the baling chamber, where it is shaped into a bale. The bale ejector is an essential component that pushes the completed bale out of the chamber. Automatic bale ejectors streamline the process, enabling continuous operation without manual intervention.

Shearing Blades

Some metal baler machines are equipped with shearing blades, which cut oversized pieces of scrap metal before they are compressed.These blades are usually crafted from hardened steel to endure frequent use and cut through tough materials.

Binding Mechanism

To secure the compressed metal into a bale, a binding mechanism is often employed. This system uses steel wires, straps, or bands to tie the bale, ensuring it remains compact and easy to transport.

Conveyor Systems

Conveyors are essential accessories for efficient operation, particularly in large-scale recycling facilities. They automate the feeding of scrap metal into the machine and can also transport finished bales to storage or shipping areas, reducing manual labor and improving productivity.

Cooling Systems

Metal baler machines generate a significant amount of heat due to the pressure exerted during operation. Cooling systems, including fans and oil coolers, help regulate the machine’s temperature, preventing overheating and ensuring continuous operation.

Wear Plates and Liners

To protect key components from wear and tear, metal baler machines are often fitted with wear plates and liners, especially in high-friction areas like the compression chamber. These components are replaceable, making them an essential accessory for extending the machine’s service life.

Oil Filtration Systems

Keeping hydraulic oil clean is crucial for ensuring the durability and efficiency of the machine’s hydraulic system. Oil filtration systems remove contaminants from the hydraulic fluid, reducing the risk of damage to internal components and ensuring smooth operation.

Safety Features

Safety accessories, including emergency stop buttons, guards, and interlock systems, are critical for ensuring operator safety during machine operation. These features prevent accidents and protect workers from potential hazards associated with the baling process.

What Materials Can Metal Balers Handle?

Metal balers are adaptable machines designed to process a broad range of materials. Common materials processed by metal balers include:

Steel

Scrap steel, including beams, pipes, sheets, and structural components from construction and demolition sites, as well as stainless steel from appliances, industrial machinery, and kitchen equipment.

Aluminum

Lightweight and durable aluminum products, such as beverage cans, siding, frames, and manufacturing scraps.

Copper

Valuable copper materials, including wires, tubing, and sheets from electrical systems, plumbing, and industrial applications.

Brass

Brass scrap from plumbing fixtures, electrical components, shell casings, and manufacturing waste.

Lead

Lead-acid batteries, lead sheets, and pipes are frequently utilized in batteries, radiation shielding, and construction materials.

Zinc

Zinc scrap, including die-casting parts, sheets, zinc-coated materials, and zinc batteries used in various electronics.

Tin

Tin-coated products, such as food packaging cans and tin-coated steel, are commonly processed by metal balers.

Nickel

Nickel scrap, including nickel alloys and battery components, is often found in stainless steel, batteries, and electronics.

Mixed Metal Scrap

One of the key advantages of metal balers is their ability to handle mixed metal scrap, such as automotive scrap, which includes steel, aluminum, and copper, and appliance scrap from refrigerators, washing machines, and stoves.

Main Considerations for Selecting Metal Balers

Choosing the right metal baler for your business requires careful consideration of several factors. Here are the key points to keep in mind:

- Type of Metal Waste: Choose a baler based on the type of metal waste you process, such as ferrous or non-ferrous metals, and the scrap’s size and condition. Different materials require specific baler sizes and capacities for efficient processing.

- Processing Capacity: Determine your processing capacity by evaluating how much scrap metal you handle regularly. Consider cycle times and bale output per hour to select a baler that matches your production needs, ensuring smooth and efficient operations.

- Bale Size and Density: Select a baler that produces bales of the ideal size and density for your storage and transportation needs. Compact, high-density bales save space and reduce transportation costs, improving overall efficiency in your operations.

- Hydraulic Power and Force: Ensure the baler’s hydraulic power aligns with the types of metal you process. Heavier materials require greater hydraulic force for efficient compression. The right hydraulic system ensures the baler performs effectively for your specific metal waste.

- Automation and Control Options: Automation features can increase efficiency. Look for fully or semi-automated balers with programmable controls and remote monitoring. These features reduce labor costs, minimize downtime, and improve operational productivity, especially in larger facilities.

- Footprint and Space Requirements: Evaluate your available space when selecting a baler. Ensure the machine fits within your facility without disrupting workflows. Compact balers are ideal for limited spaces, while larger machines suit operations with ample room for operation and maintenance.

- Maintenance and Durability: Choose a durable baler with easy maintenance requirements. High-quality construction and reliable support reduce downtime and increase machine lifespan. Consider manufacturers with good reputations for providing replacement parts and ongoing service support.

- Safety Features: Give priority to balers that have interlock mechanisms and emergency stop buttons. Compliance with industry standards ensures operator safety and reduces the risk of accidents during operation or maintenance, protecting your team and your facility.

- Budget and Total Cost of Ownership: Reflect on the overall cost of ownership, including energy usage, maintenance, and training. A higher initial investment in a quality machine may result in lower long-term costs, making it a better choice over cheaper, less efficient options.

- Customization Options: Seek out balers that offer customization features tailored to your specific requirements, such as adjustable bale sizes or specialized feeding mechanisms. Customization enhances the baler’s versatility, ensuring it meets your operational goals more effectively.

- Environmental Impact: Consider a baler’s environmental impact, focusing on energy efficiency and waste reduction. Eco-friendly features, like energy-saving hydraulic systems, help align your business with sustainability goals while reducing operational costs in the long run.

Maintenance Tips

Maintaining your metal baler properly is crucial to ensuring its durability and optimal performance. Regular maintenance activities help avoid breakdowns, minimize downtime, and prolong the machine’s lifespan. Here are some important maintenance tips for metal balers:

Regular Inspections

Regularly carry out visual inspections of the baler to spot any signs of wear and tear. Key areas to inspect include the hydraulic system, electrical components, and baling chamber. Look for leaks, frayed wires, loose connections, and worn seals. Identifying issues early can help avoid more significant damage and expensive repairs.

Hydraulic System Upkeep

The hydraulic system is critical to the operation of most metal balers, so it’s essential to keep it in good condition. Key tasks include:

- Regularly monitoring hydraulic fluid levels and refilling them when necessary.

- Inspecting hoses, fittings, and seals for leaks and repairing them promptly.

- Changing hydraulic fluid according to the manufacturer’s recommendations to prevent contamination.

Lubrication

Apply lubrication to bearings, joints, and gears consistently as per the manufacturer’s recommendations to minimize friction and reduce wear.

Blade Maintenance (For Shear Balers)

Routinely check the blades for wear, sharpening, or replacing them as needed to ensure effective cutting and compression.

Cleaning

Regularly clean the press chamber, hydraulic components, and other key areas to prevent debris buildup that can affect performance.

Electrical System Checks

Regularly inspect wiring and control panels for wear, including fraying or loose connections. Promptly address any issues to avoid electrical malfunctions.

Routine Professional Servicing

In addition to regular in-house maintenance, schedule professional servicing for more in-depth checks, such as testing hydraulic pressure, evaluating electrical systems, and inspecting internal components.

Conclusion

Whether you’re in the recycling industry or waste management, choosing the right metal baler can have a significant impact on your operations. Evaluate your needs and select a baler that meets your long-term efficiency and sustainability goals. For personalized guidance, contact a professional metal baler manufacturer who can help you customize a solution to your business needs.