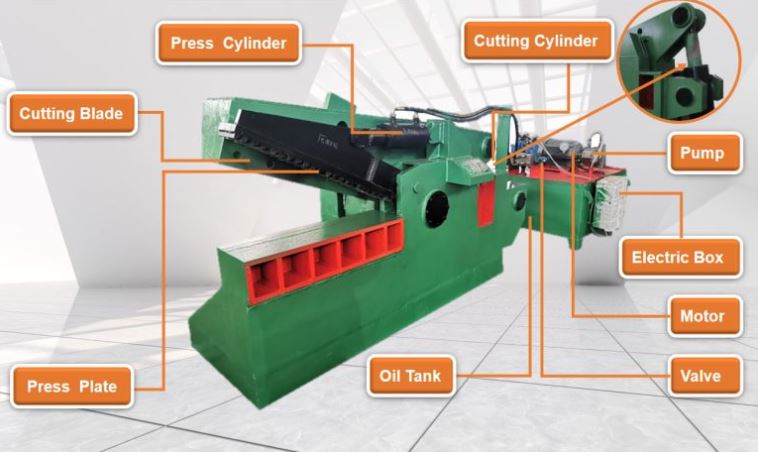

Hydraulic alligator shear machines are crucial in various industrial sectors, including scrap metal processing and manufacturing. These machines are named for their hinged jaw, powered by a hydraulic cylinder, resembling an alligator’s mouth, which shears through metal quickly.

Regular maintenance is crucial for ensuring the lifetime and effectiveness of the critical components. This article provides a detailed guide on maintaining and caring for the main components of a hydraulic alligator shear machine.

Maintain Cutting Blade

The cutting blade is a crucial element of an alligator shear machine.

- Regular Inspection And Sharpening: Check the blade for dullness or damage at regular intervals. Sharpen the blades as needed to guarantee smooth cuts and lessen the pressure on the machine.

- Replacement: If a blade becomes too worn or damaged, replace it promptly to avoid compromising the machine’s efficiency and safety.

Press Cylinder

The press cylinder is responsible for the driving force that the shear uses to cut materials.

- Seal Inspection: Frequently inspect the hydraulic seals for wear or leaks. Replace seals if necessary to prevent fluid leaks and maintain pressure.

- Rod Condition: Look for wear, corrosion, or misalignment on the cylinder rod. A damaged rod can lead to operational inefficiencies and safety hazards.

Press Plate

The press plate holds the material in place during the cutting process.

- Alignment Checks: Ensure the press plate is aligned with the cutting blade for optimal performance.

- Surface Inspection: Regularly check for any cracks or wear and repair or replace the press plate if it is compromised.

Motor

The motor powers the hydraulic pump and needs regular checks to ensure it functions efficiently.

- Cooling System: To prevent overheating, keep dust and debris from the motor’s cooling system.

- Electrical Connections: Check all electrical connections for signs of wear or corrosion. Secure any loose connections and replace damaged wires or components.

Valve

The hydraulic fluid’s pressure and flow are managed via hydraulic valves.

- Operational Testing: To ensure the valves function correctly, test them regularly. Be vigilant for unusual sounds that might indicate a potential issue.

- Cleanliness: Keep the valves clean from debris, which can cause them to stick or malfunction

Cutting Cylinder

Like the press cylinder, the cutting cylinder operates the cutting action and needs similar care.

- Leak Checks: Ensure the hydraulic fluid level is correct and conduct routine leak inspections.

- Pressure Tests: Periodically check the hydraulic pressure in the cutting cylinder to ensure it meets the required specifications for efficient operation.

Pump

The machine’s hydraulic fluid must be moved, requiring the hydraulic pump.

- Fluid Level and Quality: Regularly check the hydraulic fluid level and top it up as needed. Replace the fluid if it becomes contaminated.

- Pump Inspection: Listen for changes in noise and check for vibration, which can indicate wear or misalignment.

Electric Box

The electric box contains the electrical components that control the machine.

- Moisture and Dirt: Ensure the electric box is kept free from moisture and dirt, which can cause electrical failures.

- Component Checks: Frequently check for indications of wear or damage on all of the components inside the electric box. Replace any damaged parts immediately.

Oil Tank

The oil tank stores the hydraulic fluid necessary for the machine’s operations.

- Cleanliness: Keep the tank clean and ensure that the fluid is not contaminated with debris or water, which can damage the hydraulic system.

- Gaskets and Seals: Inspect the seals and gaskets affixed to the oil tank for indications of degradation or perforation and substitute them accordingly.

General Maintenance Tips

- Routine Cleaning: Regularly clean the entire machine to prevent debris and dust buildup, which can affect its operation and lead to premature wear.

- Lubrication: Administer lubricants to mobile components as the manufacturer indicates to guarantee seamless functionality.

- Training: To avoid mistreatment, which can result in equipment damage, ensure that all personnel are adequately trained in the machine’s operation and maintenance.

With our thorough maintenance advice, you can increase your hydraulic alligator shear machine’s performance, lifetime, and safety. Regular care prevents downtime and ensures that the machine operates at peak efficiency, contributing to your operations’ productivity and profitability.

Conclusion

Regular maintenance is essential for a hydraulic alligator shear machine’s lifetime, effectiveness, and safety. Regular checks and care of components like the cutting blade, press cylinder, motor, and valves prevent breakdowns and optimize performance.

Proper maintenance extends the machine’s life and ensures smooth functioning, lowering the risk of downtime and associated costs. Adhering to a structured maintenance routine ensures that your equipment remains reliable and effective in handling the demanding tasks of industrial environments.