As the global scrap processing industry advances, one machine is quietly transforming how high-volume scrap facilities manage quality and efficiency: the Hydraulic Scrap Bale Breaker Machine. Though compact in description, this powerful system is revolutionizing scrap metal handling and inspection on an industrial scale.

The Challenges Behind Compressed Scrap Bales

In the world of scrap metal recycling, compressed bales offer a cost-effective and space-saving solution for transporting and storing vast amounts of scrap steel. However, while these bales provide logistical advantages, they pose a major challenge: the inability to inspect the contents thoroughly.

Scrap bales often hide non-metallic materials, hazardous contaminants, or low-grade components that can disrupt downstream processes. Traditional methods of identifying these impurities are not only inefficient and labor-intensive but also inconsistent. This lack of visibility raises the possibility of supply chain conflicts, furnace damage, and lowered product quality.

As global steelmakers and recyclers raise their standards, there’s an urgent need for more advanced tools that can guarantee quality and provide assurance for every bundle that enters the system.

Introducing the Hydraulic Scrap Bale Breaker Machine

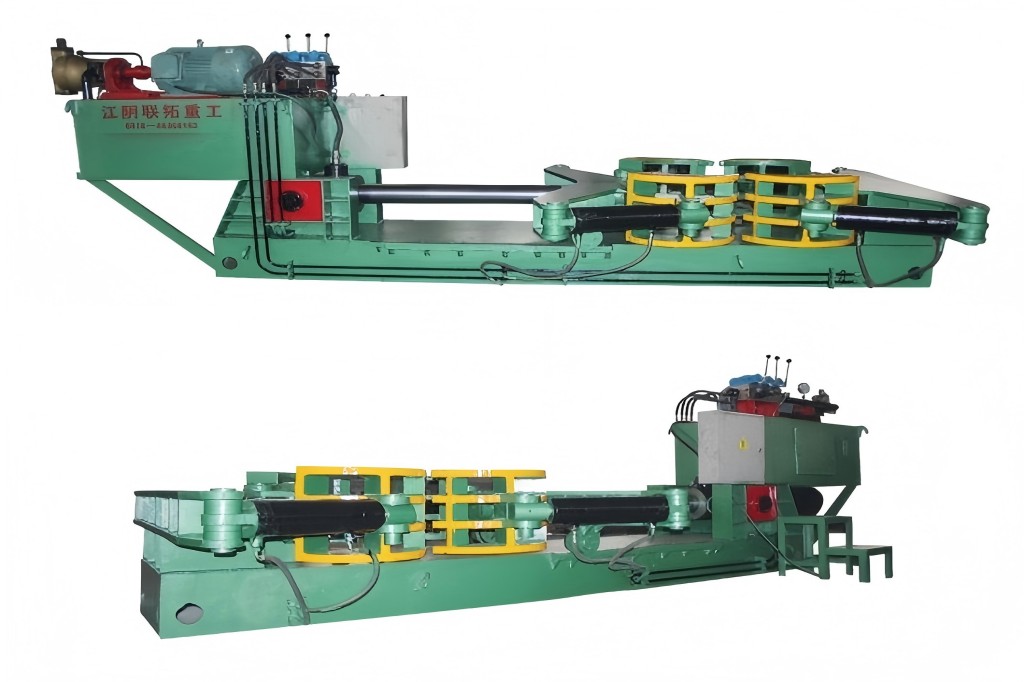

Also known in industrial circles as the press block decomposition machine, the hydraulic scrap bale breaker machine is a next-generation solution specifically designed for professional dismantling and inspection of scrap metal bales. It plays a dual role—mechanical decomposition and quality testing—allowing scrap processors to break apart densely packed bales and inspect their contents efficiently.

This machine is not merely a separator; it’s a safeguard, ensuring that every bale meets the purity and quality standards required by smelters and steel producers.

How It Works: Key Components and Structure

At the heart of the hydraulic scrap bale breaker machine lies a powerful hydraulic system that controls the forceful disassembly of tightly compressed scrap. Its robust structure is engineered for the most demanding environments, combining strength, speed, and precision.

The machine is typically composed of the following critical components:

- Motor: Drives the entire system, delivering the torque necessary for operation.

- Oil Tank and Oil Pump: Supply hydraulic fluid to power the system’s various mechanical functions.

- Hydraulic System: Converts hydraulic energy into linear mechanical motion, providing the force needed to deconstruct the bales.

- Manipulator: A mechanical arm or set of tools used to grip, rotate, or reposition the bale during the breaking process.

- Butterfly Beam: A central component that helps in applying balanced pressure on the scrap bale to split it apart without excessive energy loss.

- Main Engine: The foundational structure that houses and supports all subsystems, ensuring stability, safety, and synchronization during operation.

These elements work together to perform the delicate but demanding task of bale decomposition, allowing for a fast, safe, and complete breakdown of even the most densely compressed scrap blocks.

More Than Decomposition: A Reliable Testing Tool

One of the most significant features of the hydraulic scrap bale breaker machine is its ability to detect impurities within compressed scrap blocks. Once a bale is opened, its contents are exposed and can be visually or mechanically inspected. This capability ensures that contaminated, low-grade, or incompatible materials are identified and removed before the scrap is forwarded to furnaces or sold on the market.

This inspection step plays a critical role in:

- Maintaining scrap steel quality

- Protecting equipment in downstream processes

- Reducing production defects

- Building transparency and trust among suppliers and buyers

- Ensuring consistent pricing and stability in the scrap steel market

In an industry where quality differences can lead to significant financial impacts, such capabilities are more than advantageous—they are essential.

Industry Applications

The hydraulic scrap bale breaker machine has quickly gained ground across various sectors of the metal industry, with steel plants, smelting facilities, recycling yards, and port terminals being among the most frequent users.

- Steel Plants use the machine as a pre-processing step, ensuring that only clean, tested scrap enters their furnaces.

- Smelters depend on the machine to prevent contamination of molten metal batches.

- Recycling facilities gain from their capacity to automate a time-consuming manual procedure.

- Wharves and Port Terminals, which often receive large shipments of scrap, utilize the machine to verify shipment quality before distribution.

The machine’s versatility and reliability make it suitable for both domestic and international processing hubs, handling a wide range of ferrous and non-ferrous metals.

Economic and Operational Advantages

Beyond the obvious quality control benefits, the hydraulic scrap bale breaker machine introduces a number of operational and financial advantages that can dramatically improve a facility’s bottom line.

Increased Efficiency

The hydraulic system drastically reduces the time needed to open and inspect each bale. What might take a manual team several minutes (or even hours) to disassemble, this machine can do in seconds.

Enhanced Safety

Manual bale breaking can be hazardous. The use of mechanical manipulators and beams eliminates the need for workers to handle unstable bales, reducing injury risks.

Lower Labor Costs

By automating the dismantling process, fewer personnel are required on the floor, which lowers operational costs while improving consistency and throughput.

Reduced Waste and Rejections

Improved inspection means that impure or unusable materials are filtered out before they reach costly processing stages, preventing losses from furnace contamination or product defects.

Environmental Compliance

With global industries pushing toward stricter environmental policies, using clean, tested scrap is becoming a mandate. This machine supports sustainable operations by ensuring only acceptable materials are melted or recycled further.

Technology Integration and Smart Features

Modern iterations of the hydraulic scrap bale breaker machine come equipped with intelligent features that align with today’s smart manufacturing environments. These may include:

- Automated Controls: Touchscreen panels and programmable logic controllers (PLCs) for custom settings and precise control.

- Data Logging: Track and record inspection results, bale conditions, and material types for future traceability.

- Remote Monitoring: Some systems can be accessed and controlled remotely, offering flexibility and real-time oversight.

- Integration with Conveyors and Sorting Lines: Seamless connection to upstream and downstream equipment for a fully automated scrap processing solution.

These features not only enhance convenience but also allow facilities to better manage inventory, production planning, and compliance documentation.

Driving Quality and Market Confidence

Perhaps one of the machine’s most important long-term contributions is the restoration of confidence and stability in the scrap market. By eliminating the uncertainty surrounding bale content, it reduces the frequency of disputes between buyers and sellers. Buyers know they are receiving what they pay for, and sellers gain a reputation for quality.

This transparency encourages fair pricing, reduces the risk of litigation, and ultimately improves overall industry professionalism. Over time, it also pushes suppliers to improve their own standards, knowing that their products will be closely inspected.

The Future of Scrap Processing Is Here

As demand for high-quality recycled metal grows, especially from industries such as automotive, construction, aerospace, and electronics, the role of machines like the hydraulic scrap bale breaker becomes more significant. These industries rely on precise inputs and cannot afford material inconsistencies.

The machine stands at the intersection of automation, quality control, environmental sustainability, and industrial efficiency. It is not just a tool—it is a strategic asset for businesses looking to lead in a competitive global market.