Scrap Metal Baler Manufacturer

Our metal baler efficiently compresses various scrap metals into compact packages, including steel, aluminum, and copper.

Our scrap metal balers can be widely used in many industries, from steel mills to metal smelting and scrap yards.

You can discover the main advantages of our metal baler machine:

- Hydraulic Drive Models

- Manual / PLC Automatic Control

- No Footing Bolts for Easy Installation

- Wireless Sources / Diesel Engines Power

- 4 Bale Discharging Options

- Extrusion Pressure from 63 to 2000 tons

- Production Efficiency from 0.5 to 20 tons per hour

- Chamber and bale size can be customized

Our Main Metal Baler Machine

Y81-1250

- Nominal Force: 125 tons

- Chamber Size: 1200*700*600mm

- Bale Size: 300*300mm

- Power: 15KW

Y81-2000

- Nominal Force: 200 tons

- Chamber Size: 1600*1200*800mm

- Bale Size: 400*400mm

- Power: 37KW

Y81-2500A

- Nominal Force: 250 tons

- Chamber Size: 2000*1400*900mm

- Bale Size: 400*400mm

- Power: 2*22KW

Y81-3150A

- Nominal Force: 250 tons

- Chamber Size: 2500*2000*1200mm

- Bale Size: 600*600mm

- Power: 2*45KW

Y81-4000C

- Nominal Force: 400 tons

- Chamber Size: 5000*2000*1300mm

- Bale Size: 700*700mm

- Power: 3*45KW

Y81-6300A

- Nominal Force: 630 tons

- Chamber Size: 3000*2500*1400mm

- Bale Size: 700*700mm

- Power: 4*45KW

Our Full Metal Baler Technical Specifications

| Y81 Series Hydraulic Metal Baler Technical Parameters | ||||

| Model | Nominal Force (ton) | Chamber Size (L*W*H/mm) | Bale Size (W*H/mm) | Power (KW) |

| Y81-1250 | 125 | 1200×700×600 | 300×300 | 15 |

| Y81-1600 | 160 | 1600×1000×800 | 400×400 | 22 |

| Y81-2000 | 200 | 1600×1200×800 | 400×400 | 37 |

| Y81--2500A | 250 | 2000×1400×900 | 500×500 | 2×22 |

| Y81-2500B | 250 | 2500×2000×1200 | 500×500/600×600 | 2×30 |

| Y81-3150A | 250 | 2500×2000×1200 | 600×600 | 2×45 |

| Y81-3150B | 315 | 3000×2500×1200 | 600×600 | 2×45 |

| Y81-3150C | 315 | 3500×3000×1300 | 600×600/700×700 | 2×45 |

| Y81-4000A | 400 | 3500×3000×1300 | 700×700 | 3×45 |

| Y81-4000B | 400 | 4000×3000×1300 | 700×700 | 3×45 |

| Y81-4000C | 400 | 5000×2500×1300 | 700×700 | 3×45 |

| Y81-5000A | 500 | 3000×2500×1200 | 600×600 | 3×45 |

| Y81-5000B | 500 | 3500×3000×1300 | 700×700 | 3×45 |

| Y81-6300A | 630 | 3000×2500×1400 | 700×700 | 4×45 |

| Y81-6300B | 630 | 4000×3000×1400 | 700×700/800×800 | 4×45 |

| Y81-8000 | 800 | 3500×3000×1400 | 700×700/800×800 | 4×45 |

| Y81-10000 | 1000 | 3500×3000×1400 | 700×700/800×800 | 4×45/5×45 |

| Y81-12500 | 1250 | 3500×3000×1400 | 800×800 | 6×55 |

| Y81-15000 | 1500 | 4000×3000×1400 | 800×800 | 6×55 |

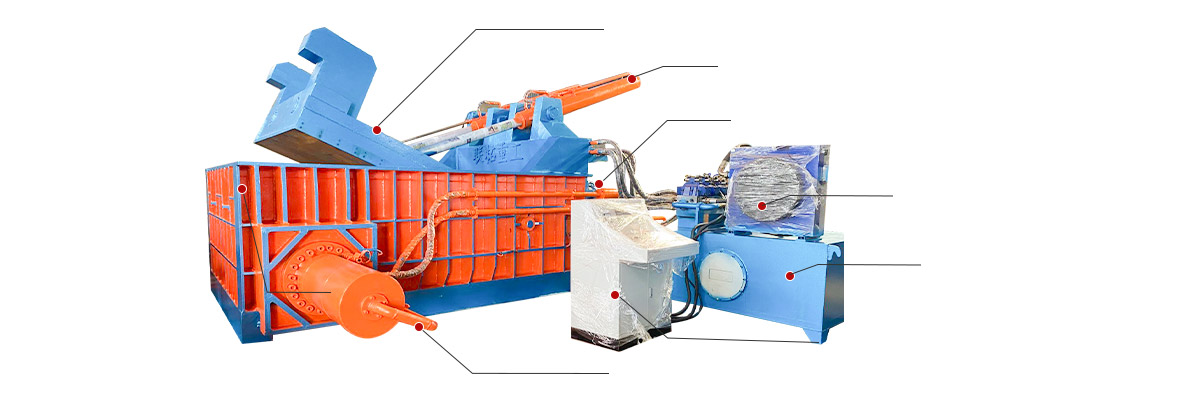

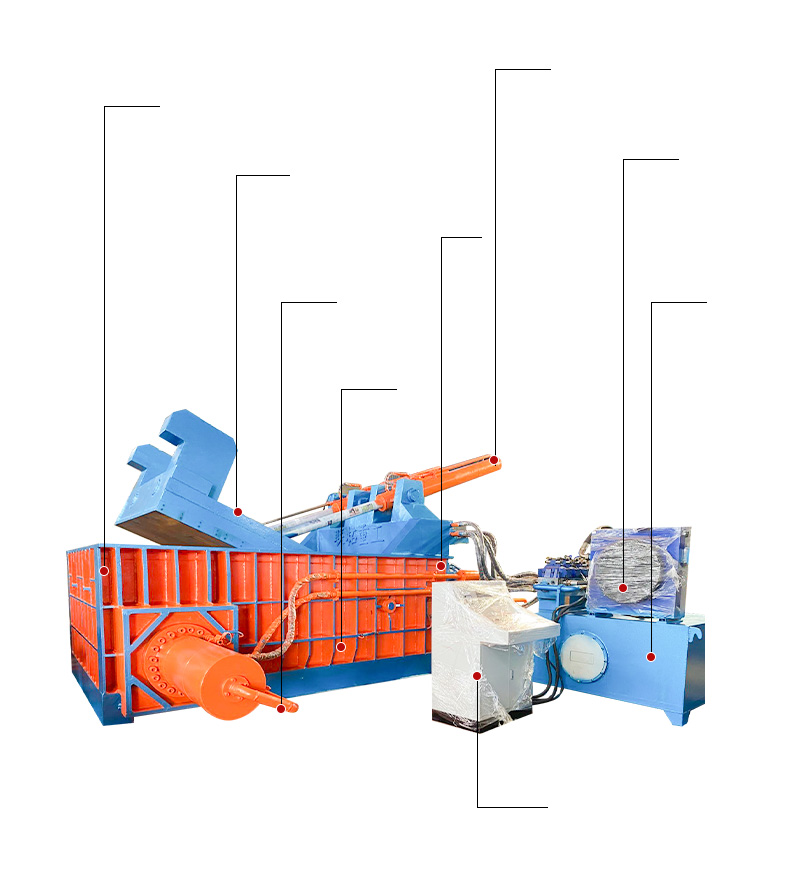

Our Hydraulic Scrap Metal Press

Door Cover

Hydraulic Station

Main Cylinder

Side Cylinder

Applications of Our Metal Recycling Baler

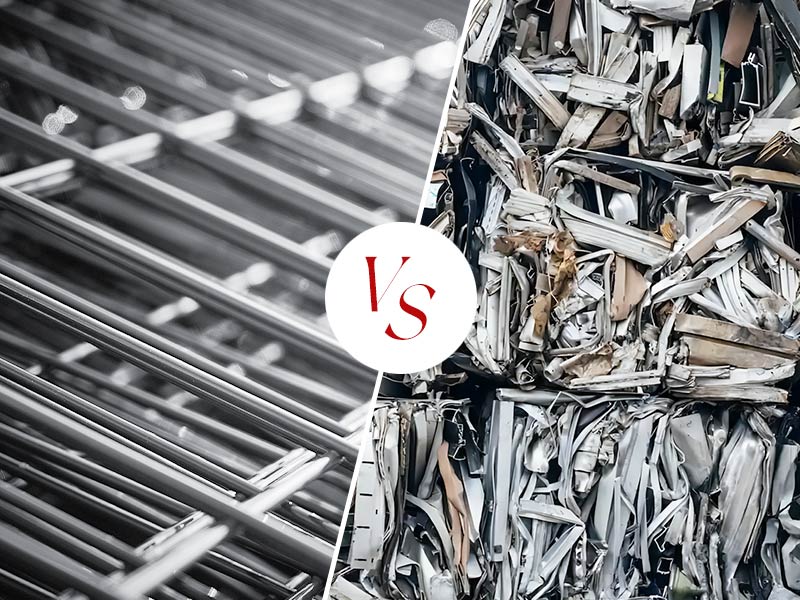

Scrap Metal

Compress scrap metal into bales with a baler for easier handling, transport, and efficient recycling.

Aluminum Cans

Aluminum scrap, such as beverage cans, aluminum siding, and extrusions, can be processed efficiently using aluminium can baler.

Aluminum Foil

Metal baler machines effectively process materials like aluminum foil, enhancing recycling by compacting various foil thicknesses into dense, manageable bales.

Stainless Steel

Steel baler are utilized to compress stainless steel scrap, including sheet metal, pipes, and other forms, into dense bales.

Scrap Car

Dismantle scrap car, shred metal, remove non-metals, and bale for efficient recycling.

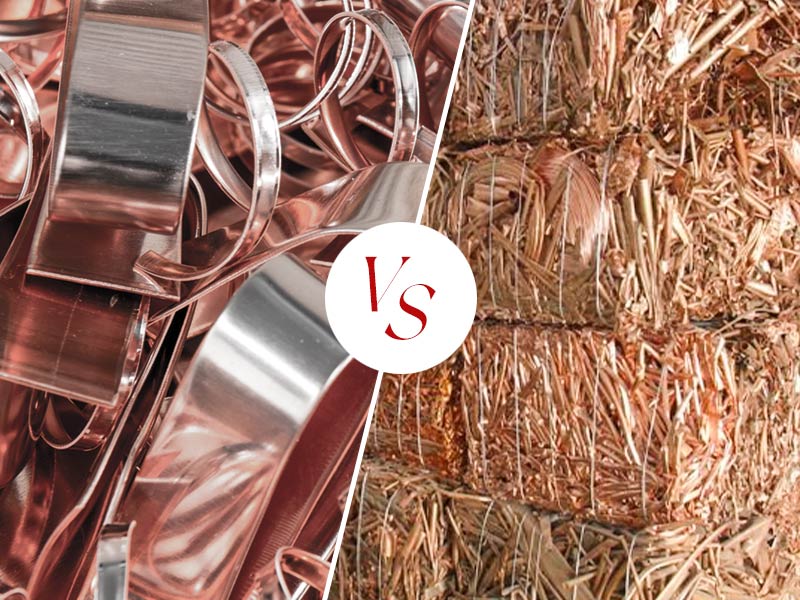

Non Ferrous Metal

Sort, clean, and compact non-ferrous metal into our non ferrous baler for improved recycling efficiency and value.

Bale Shape

Rectangular

- Pros: Efficient stacking, space-saving, versatile applications.

- Cons: May require more material, friction during transport.

Square Cube

- Pros: Stable, uniform shape, easy stacking, efficient handling.

- Cons: Less flexible, space gaps, higher material usage.

Octagonal

- Pros: Stackable, space-saving, decent structural integrity.

- Cons: Less stable stacking, potential higher production costs.