Metal Chips Briquetting Machines

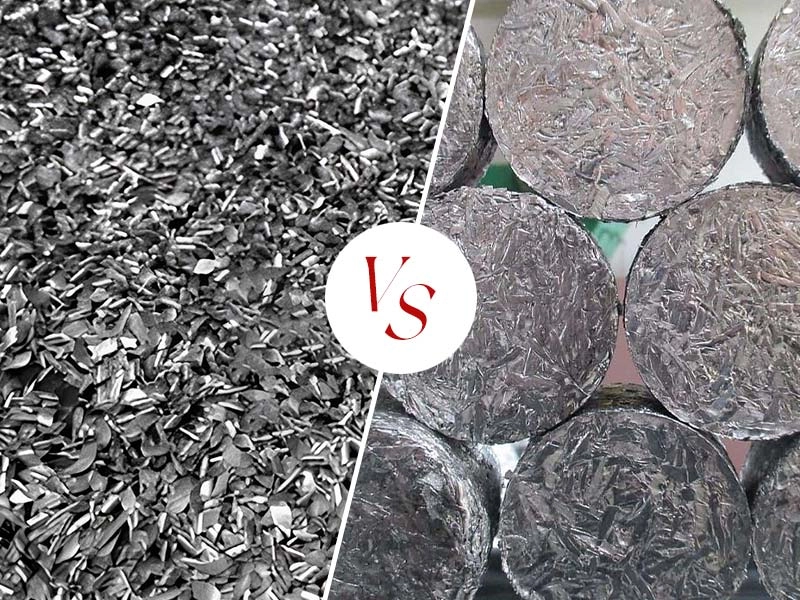

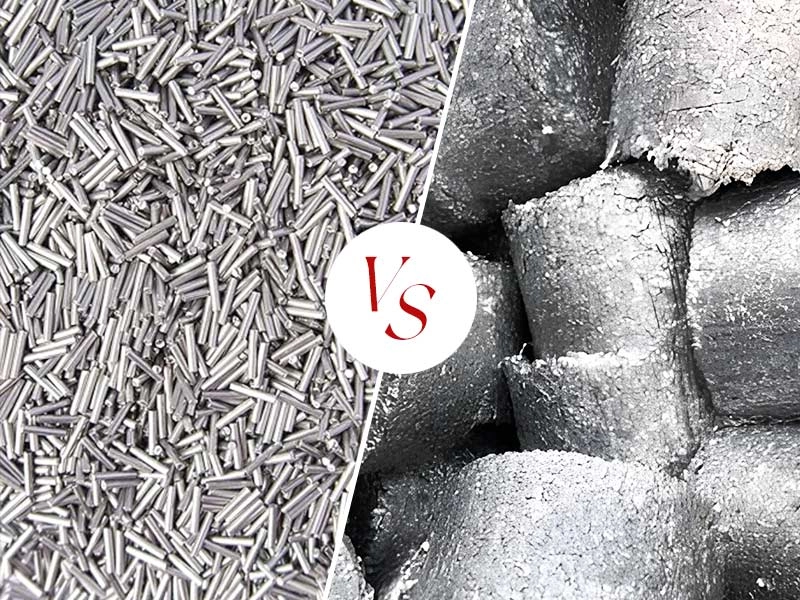

Our metal chip briquetting machine is mainly used to compress steel chips, cast iron chips, copper chips, and aluminum chips into high-density cylindrical briquettes for easy recycling and smelting.

You can discover the main advantages of our hydraulic briquette press machine:

- Hydraulic Drive

- Manual / PLC Automatic Control

- Easy Installation

- Horizontal / Vertical

- Extrusion Pressure from 250 to 1000 tons

- The size of the briquet can be customized

Our hydraulic briquette press machine

Our metal chips briquetting machine offers versatility with both vertical and horizontal configurations, providing compression for various sizes to meet diverse customer needs.

1. Horizontal Metal Briquetting Machine

Y83W-4000

- Nominal Force: 400 Tons

- Briquet Size: φ140*(70-140)mm

- Production: 2-3.5 Tons/hr

- Power: 2*30 KW

Y83W-6300

- Nominal Force: 200 tons

- Briquet Size: φ200*(160-200)mm

- Production: 4.5-55 Tons/hr

- Power: 2*45 KW

Y83W-10000

- Nominal Force: 250 Tons

- Briquet Size: φ300*(220-270)mm

- Production: 9-11 Tons/hr

- Power: 3*55 KW

2. Vertical Metal Briquetting Machine

Y83-2500

- Nominal Force: 250 Tons

- Briquet Size: φ110*(70-140)mm

- Production: 0.6-0.8 Tons/hr

- Power: 22 KW

Y83-4000

- Nominal Force: 400 Tons

- Briquet Size: φ140/160*(70-100)mm

- Production: 1.3-1.6 Tons/hr

- Power: 37 KW

Y83-5000

- Nominal Force: 500 Tons

- Briquet Size: φ160/180*(220-270)mm

- Production: 1.7--2.5 Tons/hr

- Power: 45 KW

Full Vertical Models Technical Specifications

| Y83 Series Vertical Briquette Press Machine Technical Parameters | ||||

| Model | Nominal Force (ton) | Briquet Size (L*W*H/mm) | Production (Ton/hr) | Power (KW) |

| Y83-2500 | 250 | φ110*(50-70) | 0.6-0.8 | 22 |

| Y83-3150 | 315 | φ120/140*(50-70) | 0.8-1.1 | 30 |

| Y83-4000 | 400 | φ140/160*(70-100) | 1.3-1.6 | 37 |

| Y83--5000 | 500 | φ160/180*(70-100) | 1.7-2.5 | 45 |

| Y83-6300 | 630 | φ180/200*(100-140) | 2.8-3.5 | 2×37 |

Applications of hydraulic briquette press machine

Steel Chips

Metal chips briquetting plays a crucial role in recycling, transforming steel chips from machining, cutting, and stamping processes into valuable, reusable resources.

Aluminum Chips

Aluminum chips originate from machining, cutting, and fabrication processes, efficiently recycled by an aluminum chip briquetter into reusable briquettes.

Copper Chips

Copper chips, produced during milling, turning, and drilling operations, are efficiently compacted by a copper chip briquetter for effective recycling and reuse.

Stainless Steel Chips

Stainless steel chips, generated from laser cutting, machining, and polishing, are effectively compacted by a metal chip briquetting machine for efficient recycling.

Cast Chips

Cast chips, created during the machining of cast iron and aluminum parts, are optimally compacted by a chip briquetter for streamlined recycling and reuse.

Iron Chips

Iron chips, arising from cutting, drilling, and milling of ferrous materials, are efficiently processed by an chip briquetter for enhanced recycling efforts.