Sustainable operations in today’s industrial landscape depend heavily on effective waste management. Poorly managed waste leads to increased costs, environmental harm, and inefficiencies. Hydraulic briquette press machines offer a solution by compressing waste into compact briquettes while optimizing briquette size for improved processing and storage.

This article explores how these machines operate, why briquette size matters, and the broader benefits of using hydraulic briquette press technology for waste management.

What Are Hydraulic Briquette Press Machines?

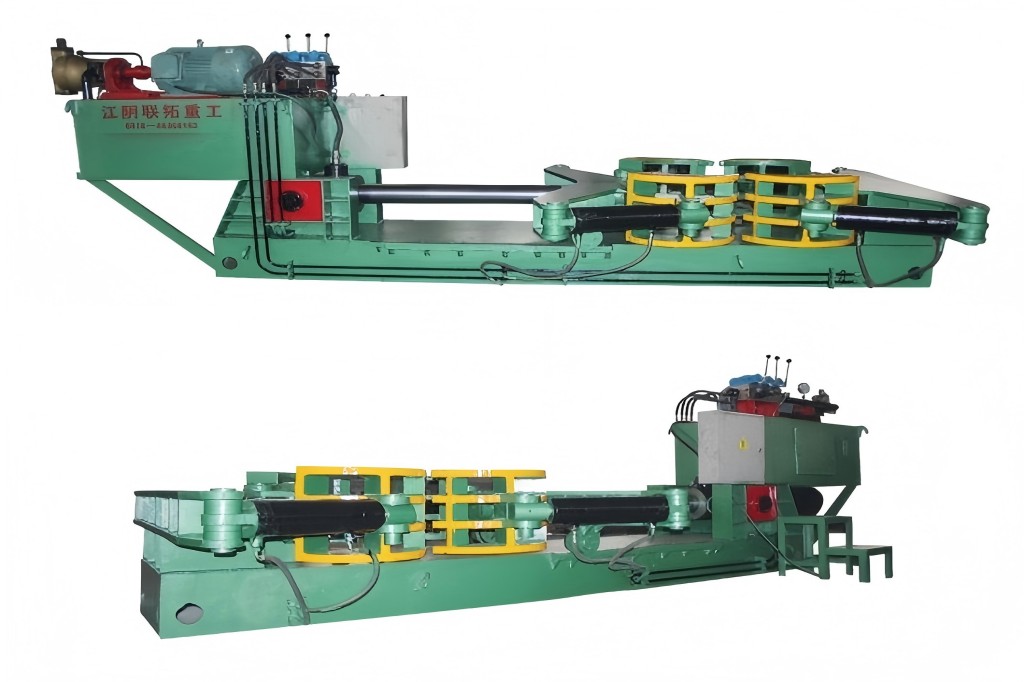

Hydraulic briquette press machines are specialized pieces of equipment designed to compress waste materials into solid briquettes. The working mechanism involves feeding the waste material into a chamber, where hydraulic pressure is applied to compress it into a uniform shape and size. This process transforms loose, bulky waste into compact briquettes, making them easier to recycle or repurpose.

Why Briquette Size Matters in Waste Management

Briquette size control is crucial to waste management process optimization. Proper briquette sizing enhances overall waste handling and storage efficiency. Briquette size directly impacts how waste is handled, stored, and transported, and it can significantly influence the overall efficiency of waste management systems.

Storage Efficiency

When waste materials are compressed into uniformly sized briquettes, they take up less space than loose waste. This reduction in size not only minimizes the footprint of storage facilities but also increases the capacity for waste storage before transportation or recycling.

Transportation Costs

Larger, bulkier waste products are more costly and difficult to transport. Compact briquettes can be packed more densely in transport vehicles, reducing the number of trips required to move waste from production sites to recycling or disposal facilities. Over time, these transportation efficiencies result in considerable cost reductions.

Recycling Efficiency

Uniformly sized briquettes streamline the recycling process. The consistency ensures that the recycling process is smoother, with less downtime due to varying sizes and shapes. Optimized briquette size enhances recycling efficiency and reduces the energy needed to process waste materials.

Waste Volume Reduction

By compressing waste into smaller, denser forms, the overall volume of waste is reduced. For sectors that regularly produce substantial volumes of waste, this is especially crucial. Briquetting helps reduce landfill trips and disposal fees and aids businesses in meeting environmental regulations.

How Hydraulic Briquette Press Machines Control Briquette Size

Hydraulic briquette press machines utilize mechanical and hydraulic systems to control briquette size with a high degree of precision. Several key features enable this level of control:

Hydraulic Pressure Control

The briquette press machine’s hydraulic system, which provides the force required to compress trash into briquettes, is its central component. By adjusting the hydraulic pressure, operators can control how tightly the material is compacted, directly influencing the size and density of the briquettes. Higher pressure yields smaller, denser briquettes, while lower pressure creates larger, lighter ones.

Die Configurations

The die is the mold through which the waste material is compressed to form briquettes. Hydraulic briquette press machines come with adjustable die configurations, allowing operators to select the desired briquette size and shape. These dies can be tailored to suit different waste types and size requirements, offering flexibility across industries.

Precision and Consistency

One of the greatest advantages of hydraulic briquette press machines is their ability to produce briquettes of consistent size and shape. This precision is essential for efficient storage, transportation, and recycling, ensuring that briquettes stack evenly and save space.

Customization for Different Materials

Various waste materials require different briquette sizes and densities. Hydraulic briquette press machines allow for precise adjustments to accommodate different waste types, from lightweight wood chips to heavy metal shavings. This flexibility enables industries to fine-tune their briquetting process to meet their specific waste management goals.

Impact on Industrial Waste Management Efficiency

Controlling briquette size significantly enhances overall waste management efficiency. Here’s how hydraulic briquette press machines contribute to more effective waste management in industrial settings:

Reduced Transportation Costs

More rubbish can be moved in one trip thanks to smaller, denser briquettes. This results in fewer travels, less fuel used, and cheaper transportation costs. For industries with high waste output, these cost savings can be substantial.

Optimized Storage

Compressing waste into uniform briquettes allows industries to store more material in the same amount of space.Businesses that operate in areas with limited storage capacity will particularly benefit from this. Optimized storage also translates into fewer waste disposal interruptions, allowing for smoother operations.

Improved Recycling Efficiency

Recycling plants prefer waste that is easy to handle and process. Uniform briquettes produced by hydraulic briquette press machines simplify recycling, as the consistent size and density ensure that the material can be processed efficiently. This reduces energy consumption at recycling facilities and minimizes the risk of downtime due to inconsistent waste.

Environmental Benefits of Hydraulic Briquette Press Machines

Hydraulic briquette press machines also play a critical role in reducing the environmental impact of waste management. By compressing waste into briquettes, these machines help industries decrease their carbon footprint in several ways:

Reduction in Landfill Waste

Briquetteing garbage lowers the total amount of material dumped in landfills. This extends the life of landfill sites and helps industries meet regulatory requirements for waste reduction. Additionally, briquetting can convert certain types of waste into recyclable or reusable materials, further minimizing the need for landfill disposal.

Lower Transportation Emissions

Compact briquettes require fewer trips to carry waste since they occupy less space, which lowers fuel usage and greenhouse gas emissions. This makes hydraulic briquette press machines an environmentally friendly solution for waste management.

Support for Circular Economy

Hydraulic briquette press machines contribute to the circular economy by converting waste into uniform, recyclable briquettes. Materials that would otherwise be discarded can be repurposed or recycled, reducing resource consumption and supporting sustainability initiatives.

Customization Options for Different Waste Types

One of the key advantages of hydraulic briquette press machines is their ability to handle a wide range of waste materials. From metal shavings and wood chips to biomass and agricultural by-products, these machines can be customized to suit various types of waste.

Metal Shavings and Chips

In industries that generate metal waste, hydraulic briquette presses are used to compress different types of metal shavings and chips into dense briquettes. This facilitates the transportation, recycling, and storage of the trash. Common metal chips processed include:

- Steel Chips: Compressed into high-density briquettes for efficient recycling and reuse.

- Aluminum Chips: Lightweight but bulky, aluminum chips can be compressed into compact briquettes for easy transport and recycling.

- Copper Chips: Known for their conductivity, copper chips are compressed for recovery and reuse in electrical applications.

- Stainless Steel Chips: Stainless steel waste is valuable, and compressing it into briquettes helps streamline the recycling process.

- Cast Iron Chips: Hydraulic briquette presses to densify cast iron chips, making them easier to transport and recycle in foundries.

- Iron Chips: Compressed iron chips are used in smelting or sold as scrap for reuse in various manufacturing processes.

Wood Chips and Biomass

For industries dealing with biomass or wood waste, controlling briquette size is crucial for producing fuel briquettes. Hydraulic presses can be adjusted to produce briquettes of the ideal size for burning in industrial boilers or for sale as eco-friendly fuel.

Agricultural By-Products

Briquetting machines are used in the agricultural industry to compress waste materials including straw, husks, and stalks. These briquettes can be used as biofuel or sold as renewable energy sources, adding value to what would otherwise be discarded waste.

Economic Benefits for Industries

Hydraulic briquette press machines offer a range of economic benefits for industries:

- Waste Reduction: By compressing waste into smaller, more manageable forms, businesses can reduce the amount of waste that needs to be transported or disposed of, cutting disposal fees and saving on transportation costs.

- Optimized Storage: Reducing the space needed to store waste allows businesses to use their facilities more efficiently. As a result, there is less need for regular waste disposal or extra storage space, which saves money.

- Increased Profitability: The ability to recycle or reuse compressed briquettes adds value to what would otherwise be discarded waste. For example, metal briquettes can be sold to recycling facilities, while biomass briquettes can be sold as fuel.

Conclusion

Hydraulic briquette press machines have revolutionized waste management by offering precise control over briquette size, making waste processing more efficient, cost-effective, and environmentally friendly. With the ability to handle various waste materials and customize briquette size, these machines play a critical role in helping industries optimize their waste management processes and reduce their environmental impact.