Product Specifications

|

Model |

Nominal Force(Kn/Ton) | Blade Length(mm) | Max Cutting Size(mm) | Shearing Frequency(times/min) |

Power(kw) |

|

Q15-630 |

630/63 |

600 |

8*600 |

4-7 |

11 |

|

Q15-1250 |

1250/125 |

800/1200 |

18*800/1200 |

5-10 |

15 |

|

Q15-1600 |

1600/160 |

1200 |

20*1200 |

5-10 |

18.5 |

|

Q15-2000 |

2000/200 |

1200 |

25*1200 |

5-10 |

22 |

|

Q15-2500 |

2500/250 |

1200 |

28*1200 |

5-10 |

37 |

|

Q15-3150 |

3150/315 |

1200/1500 |

32*1200/1500 |

4-8 |

37 |

|

Q15-4000 |

4000/400 |

1200/1800 |

35*1200/1800 |

5-10 |

44 |

|

Q15-5000 |

5000/500 |

1200/2000 |

40*1200/2000 |

5-10 |

74 |

|

Q15-6300 |

6300/630 |

900 |

45*900 |

6-10 |

90 |

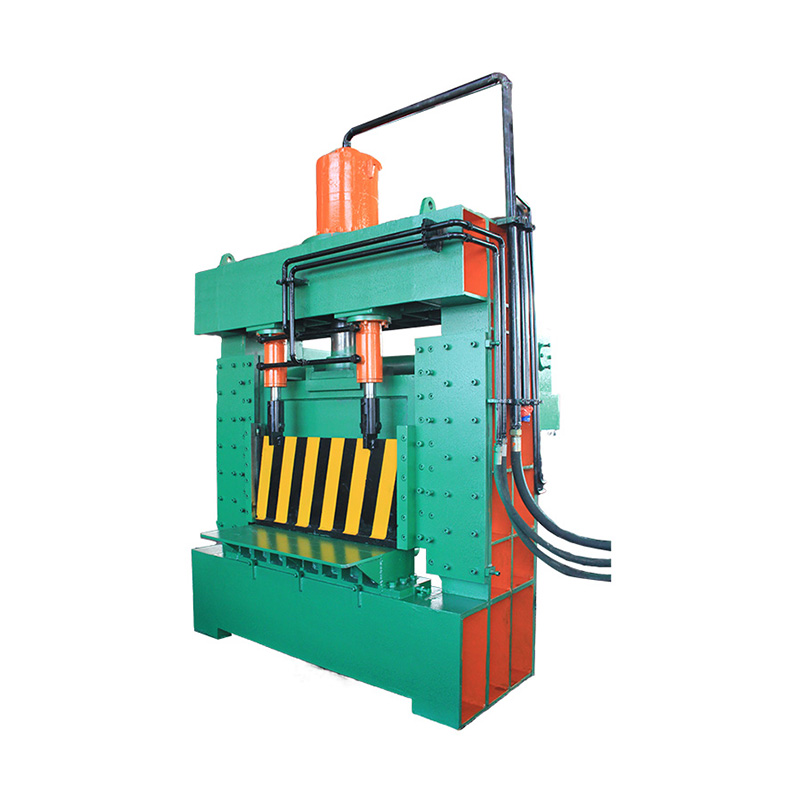

Applications

The hydraulic guillotine shear machine has extensive applications across various industries due to its ability to cut thick and heavy metal sheets precisely.

Here are some of the key industries where hydraulic guillotine shear machine is commonly used:

- Manufacturing: Employed extensively in manufacturing metal products, where precise cutting of sheets and plates is required.

- Automotive: Used in the automotive industry to cut metal for body parts and other structural components of vehicles.

- Shipbuilding: Vital for cutting steel plates and other materials used in the construction and repair of ships.

- Construction: Helps cut structural steel for buildings and other infrastructure, including beams and rebar.

- Aerospace: Used for cutting high-strength alloys and metals to fabricate aircraft parts.

- Metal Fabrication: Integral to workshops that customize metal works, aiding in cutting materials to exact specifications for various projects.

- Recycling: Used in metal recycling facilities to cut and prepare scrap metal for processing and resale.

- Railroad Industry: Assists in cutting and shaping metals used in constructing and maintaining railway tracks and machinery.

Cooperative Suppliers