Q43 Series Hydraulic Scrap Metal Alligator Shear Machine

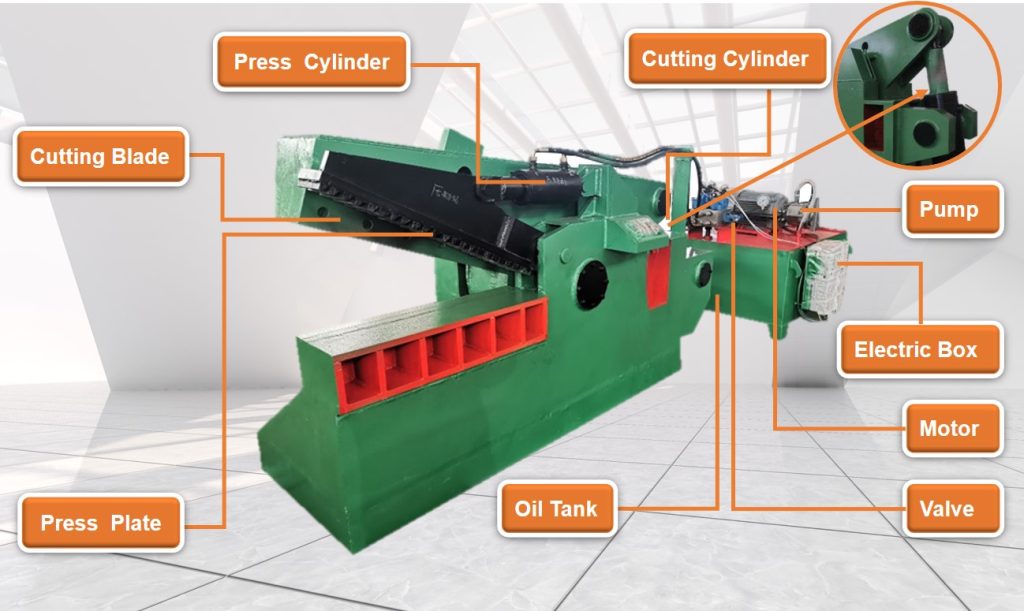

Component:

Product Specifications:

|

Model |

Max Cutting Force(Ton) | Blade Length(mm) | Max Cutting Size(mm) | Shearing Frequency(times/min) |

Power(kw) |

|

Q43-630 |

63 |

600/800 |

35×35 φ40 |

10-12 |

7.5 |

|

Q43-1200 |

120 |

600/800 |

50×50 φ55 |

10-12 |

15 |

|

Q43-1600 |

160 |

700/800 |

55×55 φ63 |

8-10 |

18.5 |

|

Q43-2000 |

200 |

800/1000 |

65×65 φ70 |

8-10 |

22 |

|

Q43-2500 |

250 |

1000/1200 |

70×70 φ80 |

6-8 |

2×15 |

|

Q43-3150 |

315 |

1200 |

75×75 φ85 |

6-8 |

2×18.5 |

|

Q43-4000 |

400 |

1200/1500 |

90×90 φ100 |

4-8 |

2×22 |

|

Q43-5000 |

500 |

1600 |

100×100 φ100 |

4-8 |

2×30 |

|

Q43-6000 |

600 |

1600/1800 |

110×110 φ120 |

4-8 |

2×45 |

Applications

Hydraulic scrap metal alligator shear machines are versatile and are used in various settings due to their robust design and efficient operation.

Here are some typical applications:

- Scrap Yards: Alligator Shear machines are essential in scrap yards for cutting metal into manageable sizes before processing or shipping.

- Recycling Facilities: They help recycle by shearing metal scraps into smaller pieces, making handling and processing various metals easier.

- Automobile Dismantling: Used in the automotive industry, especially in dismantling old or damaged vehicles to separate different metal components.

- Construction Sites: These metal shear machines are useful for cutting rebar, steel beams, and other metal construction materials on-site for more straightforward disposal or recycling.

- Manufacturing Plants: They assist in cutting off excess parts and materials in manufacturing processes, helping to maintain efficiency and reduce waste.

- Metal Fabrication Shops: Employed for precise cutting of metal sheets, bars, and other forms to specific dimensions as required in custom fabrication.

- Foundries: Useful for cutting large metal pieces and scraps into smaller, furnace-ready sizes.

- Shipbreaking: Used in breaking down ships, cutting through thick metal plates and structures efficiently.

Cooperative Suppliers

Our hydraulic scrap metal alligator shear machines feature customized, high-quality components from renowned global brands. We have maintained a decade-long partnership with leading suppliers such as Siemens, NOK Omron, Schneider, Chint, and Mitsubishi, ensuring superior performance and reliability.