What is a Hot Spinning Machine?

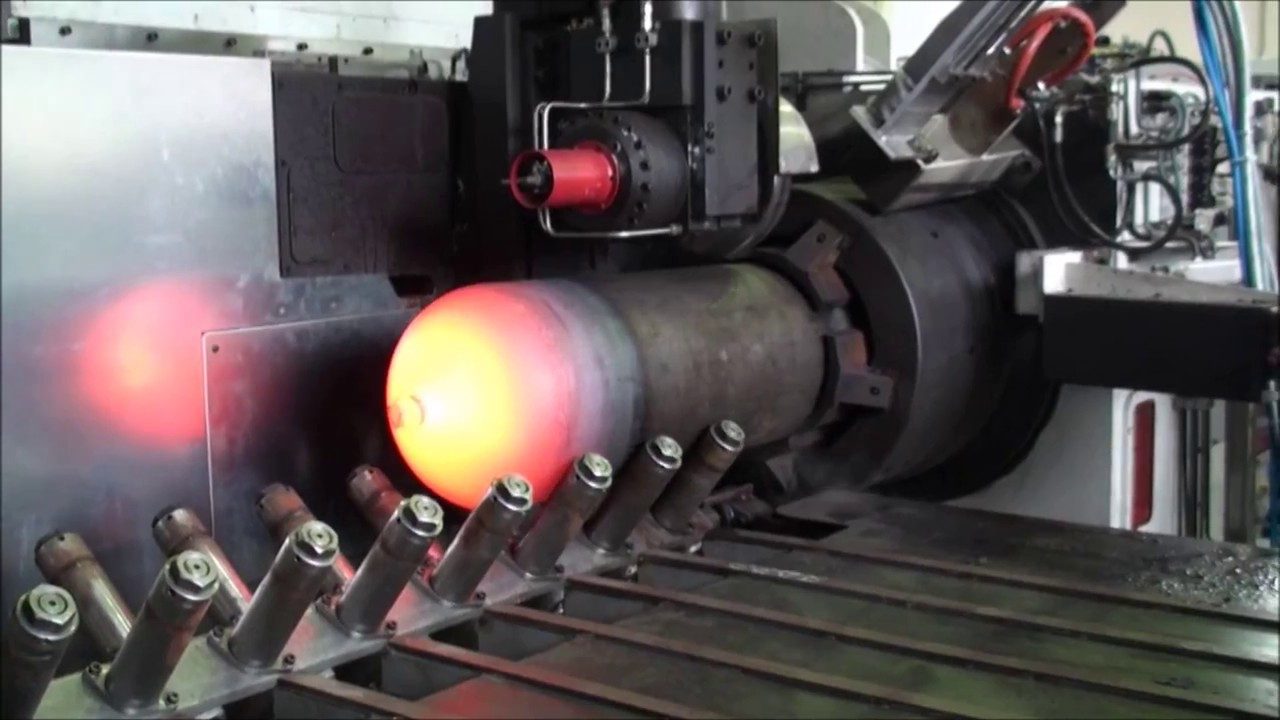

Hot spinning machine is a metalworking process that entails rotating a piece of metal on a lathe while applying intense heat from a torch to the workpiece. As the metal reaches a high temperature, it becomes malleable. At this point, shaping occurs as a specialized tool on the lathe presses against the heated surface, causing it to deform or distort as it rotates.

This method allows for the creation of complex shapes and contours with precision. Additionally, parts can be smoothly transitioned or necked down to a smaller diameter with minimal force, resulting in a seamless finish at the transition point.

Working Principle

- Place seamless pipes with a specific diameter and length into the main spindle barrel.

- Apply pressure through a hydraulic cylinder to clamp and rotate the pipe rapidly.

- Heat the head to thermoplastic temperature, then manipulate the swing cylinder piston to push the rack forward, driving gear rotation.

- Due to the rotation of the gear shaft, the closing die extrudes the thermoplastic steel tube into a certain-shaped surface.

Application

Suitable for mass production of pressure vessels such as small and medium-sized fire extinguisher cylinders, various pressure vessels, boiler collection boxes, etc.

What Materials Are Suitable for Hot Spinning?

Hot spinning is primarily used with aluminum, steel, and alloys. The choice of material depends on the application and the final product’s desired properties.

Specifications

| Model | Spindle Speed(r/min) | Clamping cylinder(KN) | Closing and grinding cylinder(KN) | Power(KW) |

| NY-180 | 350-400 | 110 | 60 | 22 |

| NY-219 | 350 | 180 | 60 | 37 |

| NY-299 | 320 | 415 | 76 | 74 |