Production detail

The metal shredder machine is a highly versatile and multi-functional device, designed with a standardized modular structure that ensures excellent parts interchangeability. It features auxiliary blades made from precision die-forged steel, enhancing durability and cutting performance.

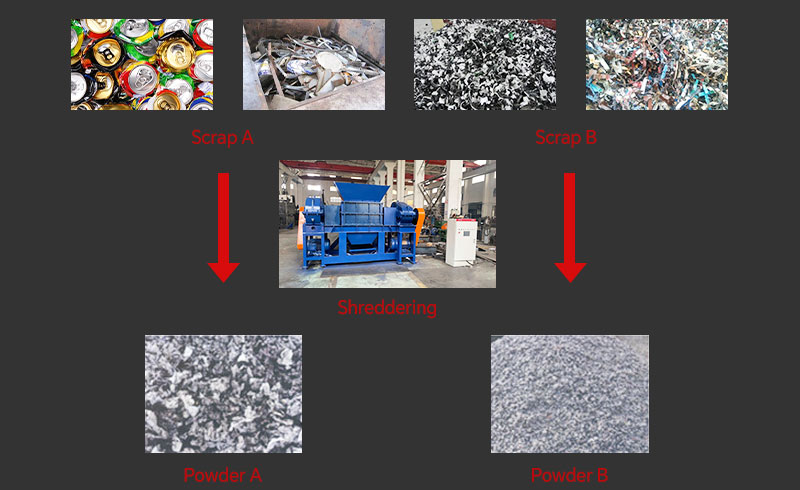

Its primary function is to shred and compress large metal materials, including oversized drums and bulky metal waste, making them more compact for efficient transportation and recycling. By reducing materials to the required sheet size, it increases accumulation density, facilitating easier handling and reuse. With a sleek design, sturdy construction, and compact build, the machine not only boosts processing capacity and shredding efficiency but also broadens its range of applications.

Widely used for crushing scrap metal, the shredder helps optimize bulk density to simplify logistics and recycling. It is particularly effective in processing paint buckets, diesel drums, thin iron sheets, car shells, compressed metal blocks, and sheet metal scraps. The blades are crafted from high-strength alloy steel, ensuring exceptional wear resistance and durability, making the machine reliable for long-term heavy-duty operations.

Features

1. The robust moving knife enhances crushing efficiency, with alloy steel casting ensuring durability and extended service life.

2 . The thick frame plate withstands high torque, providing exceptional strength and stability.

3. Equipped with a microcomputer (PLC) automatic control system, enabling start, stop, reverse, and overload protection with automatic reverse function.

4. Our metal shredder operates at low speed with high torque, producing minimal noise and dust while meeting environmental protection standards.

5. Designed for easy adjustments, low maintenance costs, and long-term cost-effectiveness.

6. The tool thickness and knife claw count can be customized to suit different material processing requirements.

Working principle of metal shredder machine

The material is fed into the shredding machine inside the box, and the material is then shredded into small pieces to meet the requirements from the lower part of the box after the shredding blade has been torn, extruded, sheared, and through other comprehensive actions.

The development of the metal shredder machine not only solves the large area of material stacking through processing, but it is also easy to transport and recycle. The most crucial parts of the process are the cutter head and motor; the metal shredder machine tears metal materials, and the requirements for the cutter head’s hardness and wear resistance are particularly high; if it is not met, the machine will be damaged.

Metal Shredder Machine Details

|

1. Metal Shredder machine blade We can customize the metal shredder machine blade for you about the raw material of the metal shredder machine. |

|

2. Control Button Our metal shredder machine has automatic control, which makes it more convenient for operating, and has simple maintenance. |

|

3. All-in-one machine Our small all-in one metal shredder machine has a special design, it covers a small area, it has Safety and Convenience Features. |

Applications

Technical Parameter

| Model | Blade Diameter(mm) | Chamber Size(mm) | Capacity(kg/h) | Power(kw) | Machine Size(mm) | Weight(kg) |

| SPJ-600 | 260 | 600×550 | 800-500 | 15 | 1800×1300×1700 | 2850 |

| SPJ-800 | 300 | 800×600 | 500-800 | 37 | 2800×1800×2100 | 4200 |

| SPJ-1000 | 350 | 1000×700 | 800-1500 | 45 | 2800×2000×2100 | 6500 |

| SPJ-1200 | 400 | 1200×900 | 1500-2500 | 55 | 2800×2500×2100 | 7800 |

| SPJ-1400 | 450 | 1400×900 | 2500-4000 | 75 | 2800×2800×2100 | 9600 |

| SPJ-1600 | 500 | 1600×1000 | 4000-6000 | 90 | 3000×2800×2100 | 12500 |

Cooperative Suppliers

Packaging

We will use wrapped film packaging or wooden packaging to protect our SPJ Series metal shredder machine, we will make good protection for our SPJ Series metal shredder machine before loading the container.