In today’s world, the environmental crisis demands urgent action to adopt sustainable practices across industries. With global waste production projected to increase by 70% by 2050, the need for efficient recycling solutions has never been greater.

Scrap metal balers play a key role in recycling by compressing metal waste into compact bales, helping industries reduce waste, conserve resources, and lower energy consumption for a more sustainable future.

A scrap metal baler: what is it?

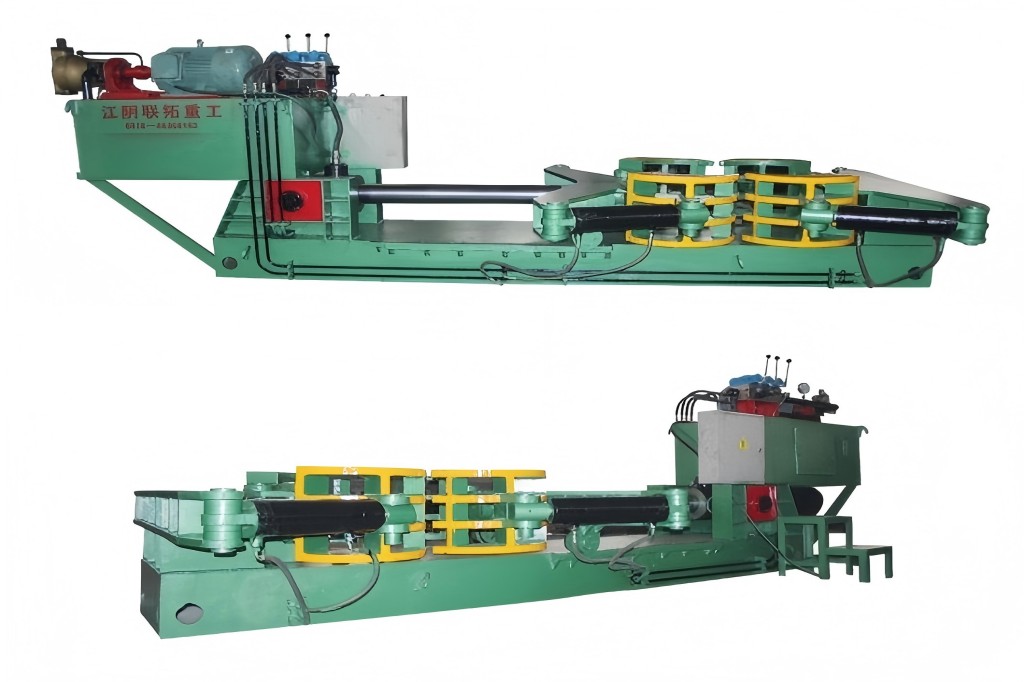

For simpler handling, transportation, and recycling, scrap metal is compressed into dense, compact bales using a scrap metal baler. It processes non-ferrous metals like brass, copper, and aluminum as well as ferrous metals like iron and steel to reduce scrap size for efficient storage and resale.

There are different types of scrap metal balers, each suited for specific applications:

| Type of Scrap Metal Baler | Description | Common Applications |

| Ferrous Metal Balers | Designed for compressing heavier metals like steel and iron. | Construction, automotive, manufacturing industries where large amounts of ferrous scrap are generated. |

| Non-Ferrous Metal Balers | Utilized for lighter metals like aluminum, copper, and brass. | Electronics manufacturing, aerospace, industries that generate non-ferrous scrap. |

| Portable Balers | Movable balers capable of being transported between different locations. | Perfect for companies operating across various scrap collection locations. |

| Fixed Balers | Larger, stationary machines used in facilities with consistent scrap metal processing. | Recycling centers, large-scale industrial facilities. |

The baling process involves feeding scrap metal into the baler, where powerful hydraulic or mechanical presses compress the metal into compact bales. Once baled, the metal can be easily stored or transported to recycling facilities, where it will be melted down and repurposed for new products.

Scrap Metal Balers’ Environmental Benefits

Waste Reduction

Scrap metal balers reduce waste by compressing large volumes of metal into dense bales, minimizing storage and transportation space. This is especially important for industries like construction and manufacturing, which generate significant metal waste.

By compressing metal scrap, balers reduce landfill waste, conserve space, and prevent contamination from decomposing metals. Efficient storage and transportation also cut down the resources needed for waste management and handling.

Reduced Energy Consumption

Recycling scrap metal with balers uses far less energy than mining and refining virgin metals like iron, aluminum, and copper. Balers require less energy since the metal is already in a usable form, needing only melting and reshaping.

For example, the use of scrap metal balers in recycling centers across the European Union has led to a significant reduction in energy consumption and emissions, saving an estimated 20 million tons of CO₂annually. Compressing scrap metal helps industries reduce greenhouse gases, combat climate change, and promote a cleaner, sustainable environment.

Conserving Natural Resources

By lowering the need to mine new raw materials, scrap metal balers help to conserve natural resources. Metals such as iron, copper, and aluminum are finite resources that are becoming increasingly scarce due to high demand. Industries can reuse current resources instead of taking new ones out of the environment by recycling scrap metal.

Reducing mining through scrap metal recycling helps protect ecosystems and wildlife. It protects natural ecosystems and promotes biodiversity by halting habitat destruction, deforestation, and soil erosion.

Contribute to Reducing Greenhouse Gas Emissions

Reducing Recycling Energy

The energy required to recycle scrap metal using balers is much lower than the energy needed to produce metals from raw ore. For instance, up to 95% less energy is needed to recycle aluminum than to create new aluminum from bauxite ore. Likewise, 60–70% less energy is required to create steel from iron ore when steel is reclaimed.

There will be a direct reduction in greenhouse gas emissions as a result of this large energy consumption reduction. Industries may significantly lessen the environmental effect of metal production and their carbon footprint by utilizing scrap metal balers.

Reducing Carbon Footprint

Businesses that use scrap metal balers to recycle their metal waste can significantly reduce their overall carbon footprint. By recycling materials instead of sending them to landfills, companies minimize the emissions associated with waste disposal, while also reducing the environmental damage caused by the extraction and processing of virgin metals.

Compressed bales are easier to transport, reducing the number of trips required to move scrap metal to recycling facilities. This reduction in transportation frequency further lowers emissions from vehicles, contributing to a more sustainable recycling process.

Transport Efficiency

One of the key benefits of scrap metal balers is their ability to increase transportation efficiency. Balers lessen the amount of material that needs to be transported by compacting metal debris into tight bales. This allows companies to fit more scrap metal into fewer loads, reducing the number of trips required to move the material to recycling facilities.

This increased transport efficiency not only reduces fuel consumption and vehicle emissions but also lowers transportation costs for businesses. By using scrap metal balers, companies can make their recycling processes more efficient and environmentally friendly.

Improve Resource Management and the Circular Economy

Promoting the Circular Economy

The concept of the circular economy is centered around the idea of reusing and recycling materials to minimize waste and reduce the need for new resource extraction. Scrap metal balers play a crucial role in promoting this circularity by enabling industries to recycle valuable materials such as iron, copper, and aluminum.

Sustainable Waste Management

Balers also contribute to sustainable waste management by converting scrap metal into a reusable form. This makes it possible for enterprises to handle garbage more effectively and in a way that complies with sustainability objectives and environmental laws. By using balers, companies can minimize the amount of waste they produce, while also reducing the environmental impact of their operations.

Reducing Industrial Waste Emissions

Industries that use scrap metal balers can reduce their overall waste generation and emissions, helping them meet environmental regulations and sustainable development goals. By recycling scrap metal, companies can avoid the environmental damage caused by mining, refining, and disposing of metal waste.

The Role of Scrap Metal Balers in Reducing Pollution

Reducing Dependence on Landfills

The contemporary era’s over-reliance on landfills for waste disposal is one of the main environmental challenges. Companies can decrease the volume of waste reaching landfills by using scrap metal balers. Compressed metal bales take up less space and are easier to manage, reducing the strain on landfill capacity.

Reducing Metal Pollution

If metal waste is disposed of in landfills, it can cause significant environmental risks. For example, metals like lead and cadmium, when left to decompose in landfills, can seep into the soil and water supply, leading to toxic contamination that can harm ecosystems and human health. Scrap metal balers mitigate this risk by ensuring that metals are properly recycled rather than left to decay in landfills.

Energy-Efficient Technology in Modern Balers

Innovations in Baler Design

Recent developments in baler technology have improved the energy efficiency and environmental friendliness of these devices. Contemporary balers are an invaluable resource for sustainable recycling because of their high performance and low energy consumption designs.

Innovations such as hydraulic efficiency, automated controls, and optimized compression mechanisms have improved the overall energy efficiency of balers. These advancements help industries reduce their energy consumption while still achieving effective scrap metal recycling.

Automation and Renewable Energy

Automated features that increase operational efficiency and lower energy waste are found in a lot of contemporary scrap metal balers. The environmental impact of some balers is further decreased by the fact that they run on renewable energy sources like solar or wind power.

Automation also allows for more precise control of the baling process, minimizing the amount of energy required to compress and process scrap metal. This combination of automation and renewable energy makes modern balers a key part of sustainable industrial operations.

Long-Term Environmental Impact

Energy-efficient scrap metal balers contribute to long-term environmental sustainability by reducing energy consumption, minimizing waste, and promoting recycling. Industries may dramatically reduce their environmental impact and raise their overall sustainability profile by investing in these equipment.

Businesses’ Economic and Environmental Gains

Cost Savings

Businesses can save a lot of money by investing in scrap metal balers. By compressing scrap metal into bales, companies can reduce their waste disposal costs and save on the expenses associated with landfill use. Additionally, the compact size of bales reduces transportation costs by allowing companies to move more scrap metal in fewer trips.

Additionally, recycling waste metal lessens the need to spend money on costly new raw material purchases. By utilizing balers to recycle existing materials, companies can reduce raw material expenses and boost their profitability.

Enhancing Corporate Social Responsibility (CSR)

Using scrap metal balers also enhances a company’s corporate social responsibility (CSR) profile. Companies that put sustainability and environmental conservation first are frequently seen more positively by investors, regulators, and customers. By investing in balers and committing to recycling, companies can demonstrate their commitment to reducing waste and protecting the environment.

Complying with Environmental Regulations

Many industries are subject to strict environmental regulations related to waste management, recycling, and emissions reduction. Scrap metal balers enable businesses to handle their garbage more efficiently and lessen their environmental impact, which helps them comply with these rules.

By using balers, companies can meet regulatory requirements while also improving their sustainability practices and reducing the risk of penalties for non-compliance.

Conclusion

For businesses, the economic and environmental benefits of using scrap metal balers are clear. From cost savings and enhanced CSR to compliance with environmental regulations, balers offer a sustainable solution to managing industrial waste.

As we move toward a more sustainable future, adopting technologies like scrap metal balers is essential for industries looking to make a lasting environmental impact. By choosing to recycle and conserve resources today, we can pave the way for a cleaner, greener tomorrow.