Building a scrap yard is an exciting business opportunity in today’s world, where recycling and resource recovery are gaining significant attention. On the other hand, establishing and running a scrap yard necessitates having a complete grasp of the associated expenses and advantages.

This article provides an in-depth look at the advantages, and investment requirements for different scales of operations, and steps to calculate the return on investment (ROI).

The Benefits of Building a Scrap Yard

Building a scrap yard comes with numerous advantages for businesses. Below is a list of the key benefits, each providing significant value in terms of cost savings, environmental sustainability, and revenue generation:

Boosting Revenue Through Recycling

Scrap yards generate revenue by buying recyclable materials like metal, paper, and electronics at low prices and reselling them for profit. This constant revenue stream helps businesses diversify income sources.

Reducing Waste Disposal Costs

Owning a scrap yard allows businesses to minimize their waste disposal expenses. Instead of paying high fees to landfill operators, businesses can repurpose and recycle materials, cutting overall waste management costs.

Increasing Sustainability in the Environment

Scrap yards help to lessen pollution in the environment and the depletion of natural resources through recycling materials. Businesses gain a reputation for sustainability, appealing to eco-conscious customers and stakeholders.

Securing Tax Incentives

Governments frequently offer tax exemptions or other incentives to companies that reduce their waste and recycle. These savings can significantly offset the initial costs of setting up a scrap yard, enhancing profitability.

Enhancing Supply Chain Efficiency

Scrap yards can directly support a business’s supply chain by providing consistent access to recycled raw materials, reducing dependency on external suppliers and mitigating price fluctuations for new materials.

Enabling Customized Scrap Solutions

Businesses with in-house scrap yards have greater flexibility in customizing recycling and disposal solutions for their specific waste streams. This control optimizes operations and increases overall efficiency.

Improving Resource Recovery Rates

Scrap yards allow businesses to maximize resource recovery from industrial processes, converting waste into valuable commodities. This reduces overall resource consumption and enhances operational sustainability.

Fostering Long-term Financial Stability

Establishing a scrap yard offers businesses long-term financial stability by creating a reliable revenue stream and reducing the costs of waste management and material procurement.

Factors to Consider When Building a Scrap Yard

When planning a scrap yard, several key factors must be taken into account to ensure smooth operations and long-term profitability:

- Location and Land Costs: Choosing the right location is critical. According to the U.S. Environmental Protection Agency (EPA) – Industrial Site Zoning regulations, scrap yards must be located in industrial areas and comply with local regulations, which vary from state to state. In addition, proximity to urban areas, transportation hubs, and recycling centers should be considered for logistical efficiency.

- Environmental Permits and Compliance: Scrap yards generate waste and emissions, making environmental compliance crucial. Businesses need to secure air quality permits, water discharge permits, and hazardous waste handling approvals.

- Infrastructure and Facility Design: The design of the scrap yard must account for processing, sorting, and storage areas. Facilities should have drainage options, stormwater management systems, and safe storage for hazardous items. According to the Scrap Recycling Industries (ISRI) guidelines, proper facility design also ensures compliance with health, safety, and environmental regulations.

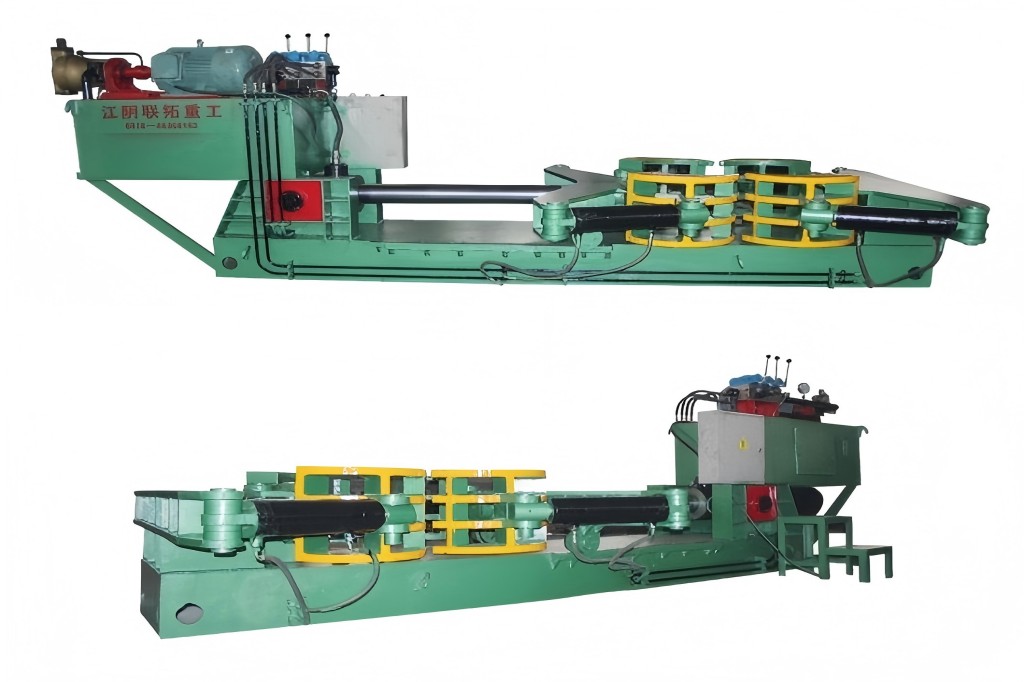

- Equipment and Machinery Investment: Scrap yards require specialized equipment like shredders, cranes, balers, and sorting machines. These come with significant costs, ranging from $500,000 to over $1 million, depending on yard size. Regular maintenance and upgrading are necessary to maintain operational efficiency and reduce downtime.

- Labor Force and Safety Standards: Hiring and training skilled workers is critical for safe yard operations. OSHA mandates specific safety protocols, including personal protective equipment (PPE), proper training, and emergency response plans. Allocating funds for continuous safety training ensures compliance and reduces accident-related liabilities.

- Transportation and Logistics Costs: Transporting scrap materials requires a reliable fleet of trucks or partnerships with haulers. Businesses should factor in fuel costs, vehicle maintenance, and driver wages. Optimizing routes and using efficient vehicles can reduce logistics expenses, while proximity to buyers and suppliers lowers transport costs.

- Security Systems and Asset Protection: Due to the high value of scrap materials, security is essential. Installing surveillance cameras, fencing, and alarm systems reduces theft risks. Additionally, employing 24/7 monitoring and strict access control measures will protect against internal and external theft.

- Liability and Insurance Coverage: Adequate insurance protection is essential. Businesses need liability insurance to cover worker injuries, environmental damage, and theft . Due to the inherent hazards, scrap yards frequently have high insurance premiums; yet, having the right coverage shields the company from financial damages in the event of an accident or legal action.

- Automation and Technology Integration: Investing in technology, such as automated sorting and inventory tracking systems, can improve productivity by reducing manual sorting errors. Although the initial cost is high, these systems boost long-term efficiency and accuracy, allowing the yard to handle greater volumes of materials effectively.

Cost of a Small Scrap Yard

A small scrap yard typically involves an initial investment ranging from $50,000 to $200,000, with the bulk of costs attributed to machinery and land.

Investment Breakdown

- Land Purchase or Lease: 2–5 acres of land, depending on location, will cost between $10,000 and $50,000.

- Machinery Investment: Small Baler: Essential for compacting scrap materials, costing around $10,000.

- Hydraulic Shears: Used to cut metals, priced at approximately $20,000.

- Small Metal Shredder: A basic shredder for processing scrap metal can cost about $30,000.

- Storage Facilities: Basic storage units such as containers or open yards for organizing materials cost $5,000 to $15,000.

- Licensing and Permits: Regulatory requirements, including environmental permits, will amount to $5,000 to $10,000.

- Labor and Operational Costs: Employing a team of 3–5 workers, including a manager and operators, costs around $60,000 annually.

- Security Measures: Basic security setup, including fencing and cameras, will cost $5,000 to $10,000 to secure valuable scrap materials.

Cost of a Medium-Sized Scrap Yard

A medium-sized scrap yard requires an initial investment of $200,000 to $750,000, with a focus on larger machinery and more extensive land use.

Investment Breakdown

- Land Purchase or Lease: 5–10 acres of land, priced between $50,000 and $150,000 depending on location.

- Machinery Investment: Industrial Baler: Larger capacity balers are required, costing around $30,000.

- Large Hydraulic Shears: Industrial-grade shears are necessary for cutting thicker metals, priced at approximately $75,000.

- Industrial Metal Shredder: A heavy-duty shredder for high-volume scrap processing costs around $100,000.

- Conveyor System: For efficient material movement and sorting, a conveyor system will cost between $50,000 and $100,000.

- Material Sorting Equipment: Automated sorting systems for separating ferrous and non-ferrous materials can range from $50,000 to $100,000.

- Storage and Warehousing: Larger, more robust storage units or open warehouses for materials, costing $20,000 to $50,000.

- Licensing and Compliance: More comprehensive environmental assessments and permits, costing $10,000 to $20,000.

- Labor and Staffing: Employing 10–15 workers, including skilled machine operators and supervisors, with an annual labor cost of around $200,000.

- Security and Surveillance: Enhanced security measures, including monitored alarm systems and security fencing, costing $15,000 to $25,000.

Cost of a Large Scrap Yard

A large scrap yard demands a considerable investment ranging from $750,000 to $2,000,000, driven by the need for advanced machinery, extensive land, and high-level automation.

Investment Breakdown

- Land Purchase or Lease: 10–20 acres of land, with costs ranging from $150,000 to $500,000, depending on the geographic location and accessibility.

- Machinery Investment: Heavy-Duty Metal Shredder: High-capacity shredders for processing large volumes of scrap metal, costing approximately $250,000.

- High-Volume Industrial Baler: Capable of handling large amounts of scrap, priced around $100,000.

- Cranes and Lifting Equipment: Heavy-duty cranes for moving large metal pieces, costing about $150,000.

- Automated Sorting and Conveyor Systems: Advanced sorting systems, including magnetic and optical sorters, will cost between $200,000 and $500,000.

- Storage and Specialized Facilities: Building warehouses and covered storage areas for high-value or hazardous materials, ranging from $100,000 to $250,000.

- Regulatory Compliance and Environmental Impact: Extensive environmental studies and ongoing compliance costs can amount to $20,000 to $50,000, depending on regional regulations.

- Labor and Staffing: Employing 20–50 workers, including engineers, operators, and managers, with annual labor costs ranging from $500,000 to $1,000,000.

- Safety and Security Systems: Advanced security, fire protection, and health and safety systems will cost between $50,000 and $100,000 to ensure the site is fully protected.

Calculate the Return on Investment (ROI)

Calculating the return on investment (ROI) is crucial when establishing a successful scrap yard. ROI enables companies to calculate the speed at which they may turn a profit and recoup their initial expenditure. Here’s a concise guide to calculating ROI with an example.

Calculation Steps for ROI

Step 1: Determine Total Initial Investment

The first step is calculating the total upfront costs. This includes land acquisition, machinery (such as metal baler machines, metal shear machines, briquette press machines, scrap grabs, etc.), construction, labor, and utilities. These are the key components that make up the initial capital expenditure.

For example, the cost categories for a medium-sized scrap yard might include:

- Land acquisition

- Machinery purchases

- Construction and infrastructure

- Waste management systems

- Labor for initial setup

Step 2: Estimate Annual Revenue

Annual revenue refers to the income generated from processing and selling scrap metal. The amount of revenue largely depends on the scrap volume processed and the selling price of different materials like copper, aluminum, and steel.

Revenue can be calculated as:

Revenue = Price per Ton of Scrap × Number of Tons Sold Annually

Step 3: Estimate Annual Operating Costs

Operating costs are the recurring expenses needed to keep the scrap yard functional. These typically include:

- Employee wages

- Utility bills (electricity, water, waste disposal)

- Equipment maintenance

- Miscellaneous costs such as fuel and transportation

The profit margin is calculated by deducting these expenses from revenue.

Step 4: Use the ROI Formula

Once you have the total investment, annual revenue, and annual operating costs, the ROI can be calculated using the following formula:

ROI = (Annual Revenue – Annual Operating Costs) / Total Initial Investment × 100

Example Calculation

Let’s assume a business plans to build a medium-sized scrap yard. The following are estimated financial figures:

- Total Initial Investment: $1,000,000 (This includes land acquisition, machinery, construction, etc.)

- Annual Revenue: $1,500,000 (Based on processing and selling various types of scrap metals)

- Annual Operating Costs: $800,000 (This includes labor, utilities, and maintenance costs)

Using the ROI formula:

ROI = (1,500,000 – 800,000) / 1,000,000 × 100 = 70%

Interpretation of the Result:

An ROI of 70% means that the business will recover 70% of its initial investment within the first year of operation. It would take approximately 1.43 years (100/70) to fully recoup the initial investment, assuming stable revenue and operating costs.

Conclusion

Establishing a scrap yard promotes environmental sustainability and provides businesses with a wealth of alternatives for cost and revenue savings. Whether planning a small, medium, or large yard, understanding the associated costs and ROI calculation is essential to making informed decisions.

By carefully considering equipment needs, labor costs, and market demand, businesses can maximize the profitability of their scrap yard operations.