Gantry shears are essential in scrap metal processing and recycling, cutting large metal materials into manageable pieces with precision, making them indispensable for heavy-duty industrial applications.

Adhering to quality standards ensures gantry shears operate safely and efficiently, preventing accidents, reducing downtime, and avoiding costly maintenance or catastrophic failures.

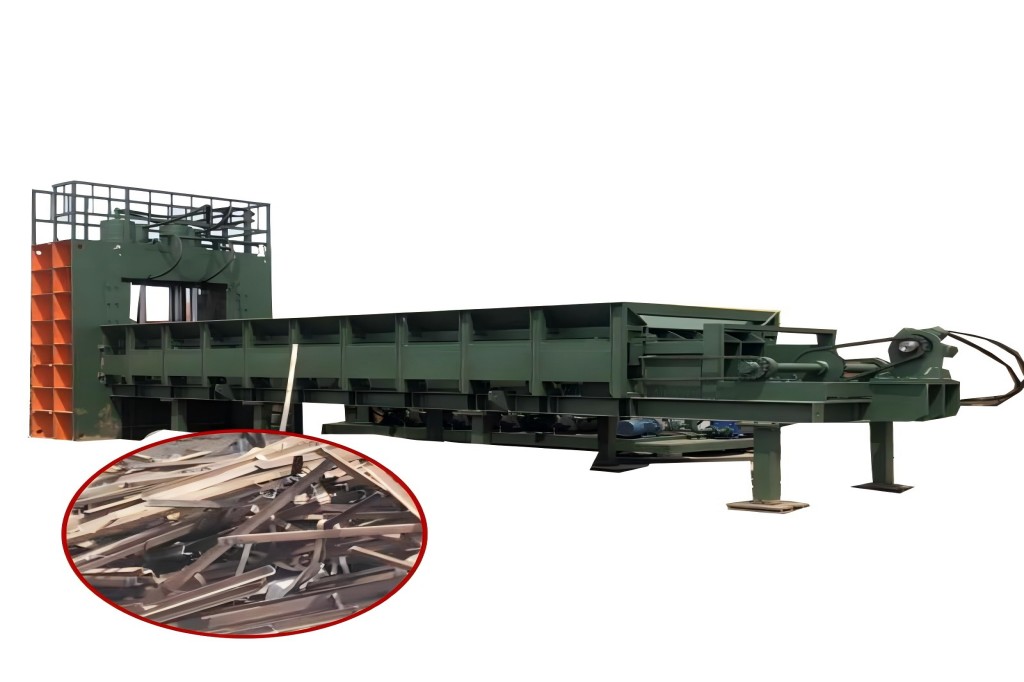

Understanding Gantry Shears

Gantry shears are large, heavy-duty machines specifically designed for cutting thick and large metal materials. They consist of a gantry, or a large overhead framework, equipped with a powerful cutting blade or torch. This configuration allows for the precise and forceful cutting of metals, a necessity in industries that deal with substantial metal volumes.

These machines are commonly used in scrap yards, steel mills, and recycling plants where they play a critical role in reducing the size of metal scraps and preparing them for further processing, melting, or reuse. The robust design of gantry shears enables them to handle tough materials such as steel, iron, and other ferrous and non-ferrous metals, making them a key asset in the metal processing industry.

Material Quality

The construction of gantry shears must involve the use of high-quality materials to ensure durability, efficiency, and safety. The following material specifications are essential:

- Strength: Gantry shears must be constructed from materials with high tensile strength to withstand the enormous forces exerted during the cutting process.

- Wear Resistance: The components, particularly the blades, should be made from wear-resistant materials like high-carbon steel or tungsten carbide to ensure longevity and reduce the need for frequent replacements.

- Corrosion Resistance: Given the harsh environments in which gantry shears operate, the materials used should have excellent corrosion resistance to prevent degradation from exposure to moisture and chemicals.

- Heat Resistance: The materials should maintain their structural integrity at high temperatures, which are common during the cutting of thick metal sheets.

Using substandard materials can lead to premature wear and tear, frequent breakdowns, and increased safety risks, highlighting the necessity of adhering to high material quality standards.

Accuracy and Precision

Gantry shears require precise and accurate operation to function well. These machines must perform cutting operations with a high degree of accuracy to ensure that the metal pieces produced are within the required specifications. The following aspects are crucial for maintaining precision and accuracy:

- Cutting Accuracy Standards: Gantry shears should meet specific cutting accuracy standards, which define the allowable deviation in the cut size. Typically, a deviation of no more than ±1 mm is acceptable for most industrial applications.

- Measurement Tools: Accurate measurement tools, such as laser distance meters or micrometers, should be integrated into the gantry shears to continuously monitor and adjust the cutting process.

- Calibration and Maintenance: Regular calibration of the cutting tools and sensors is necessary to maintain accuracy. This entails ensuring peak performance by examining the cutting edge’s state and the blades’ alignment.

Precision in cutting not only enhances the quality of the output but also reduces material wastage and improves overall operational efficiency.

Safety Requirements

An essential consideration when using gantry shears is safety. Several safety features on these devices are intended to safeguard operators as well as nearby personnel. The fundamental standards for safety are as follows:

- Emergency Stops: In the event of an emergency, gantry shears should have readily available emergency stop buttons that let users stop the machine right away.

- Guard Systems: To avoid unintentional contact with the blades or moving parts, protective guards should be erected around the cutting area.

- Operator Protection: Personal protective equipment (PPE) such as gloves, helmets, and safety glasses should be mandatory for operators to shield them from flying debris and sharp edges.

- Safety Standards Compliance: Gantry shears must abide by global safety standards, including those set forth by the Occupational Safety and Health Administration (OSHA) and the ISO (International Organization for Standardization). Compliance ensures that the machines are designed with the highest safety considerations in mind, reducing the risk of accidents.

Adhering to these safety requirements not only protects human lives but also ensures the smooth operation of the machinery.

Structural Integrity

The structural integrity of gantry shears is fundamental to their ability to perform under heavy loads and high-stress conditions. The frame of the gantry shear must be robust enough to support the weight and force exerted during the cutting process. Key considerations include:

- Frame Strength: The frame should be constructed from high-grade steel or other equally strong materials to withstand the stress and strain of heavy-duty operations.

- Quality Inspections: Regular quality inspections, such as non-destructive testing (NDT), should be conducted to detect any structural weaknesses or defects in the frame.

- Load Testing: Gantry shears should undergo load testing to verify that the structure can handle the maximum operational load without any deformation or failure.

Ensuring structural integrity is essential for the longevity and reliability of the gantry shear, preventing costly repairs and potential machine failures.

Performance Efficiency

Performance efficiency in gantry shears is measured by the speed and consistency with which the machine can cut through materials. The following factors contribute to the efficient performance of gantry shears:

- Cutting Speed: The machine should be capable of cutting at a fast rate without compromising accuracy or safety. This is frequently accomplished by utilizing strong electrical or hydraulic systems.

- Consistency: The machine must deliver consistent performance, maintaining the same level of accuracy and speed across multiple operations.

- System Efficiency: Efficient hydraulic or electrical systems are crucial for maintaining the performance of gantry shears. These systems ought to be built with the greatest cutting power and the least amount of energy usage.

High-performance efficiency translates to increased productivity and reduced operational costs, making it a critical quality requirement for gantry shears.

Maintenance and Durability

To ensure long-term durability, gantry shears must be designed with maintenance in mind. Regular maintenance helps prevent breakdowns and extends the life of the machine. Important features include:

Maintenance Ease: The gantry shear’s design should make it simple to reach important parts for upkeep and repairs.

Wear-Resistant Parts: Components such as blades and hydraulic systems should be made from materials that resist wear, reducing the frequency of part replacements.

Preventive Maintenance Programs: Implementing a preventive maintenance program that includes regular inspections, lubrication, and part replacements can significantly extend the life of the equipment.

Gantry shears must be long-lasting and simple to maintain in order to reduce downtime and guarantee their long-term dependability.

Industry Standards and Certifications

Gantry shears are made to the greatest quality and safety requirements, thus they have to meet a number of industry certifications and norms. These certifications serve as a benchmark for quality and provide assurance to customers. Key certifications include:

- ISO Certification: Ensures that the gantry shears meet international standards for quality management and performance.

- CE Certification: shows that the gantry shears meet the environmental, health, and safety requirements of the European Union.

- Third-Party Certifications: Independent third-party certifications provide additional validation of the quality and safety of the gantry shears, enhancing customer confidence.

gantry shears wholesale manufacturer must demonstrate their commitment to quality and safety by meeting certain industry standards and acquiring certifications.

Conclusion

Gantry shears play a crucial role in the metal processing industry, and their quality requirements are vital to ensuring effective, efficient, and safe operations. By adhering to stringent standards for material quality, precision, safety, structural integrity, performance efficiency, maintenance, and industry certifications, manufacturers can produce gantry shears that meet the demanding needs of industrial applications.