Scrap metal recycling is a key industry that plays a role in turning waste materials into valuable resources. Among the critical pieces of equipment used in this industry are shears—machines designed to cut through various metal types and sizes.

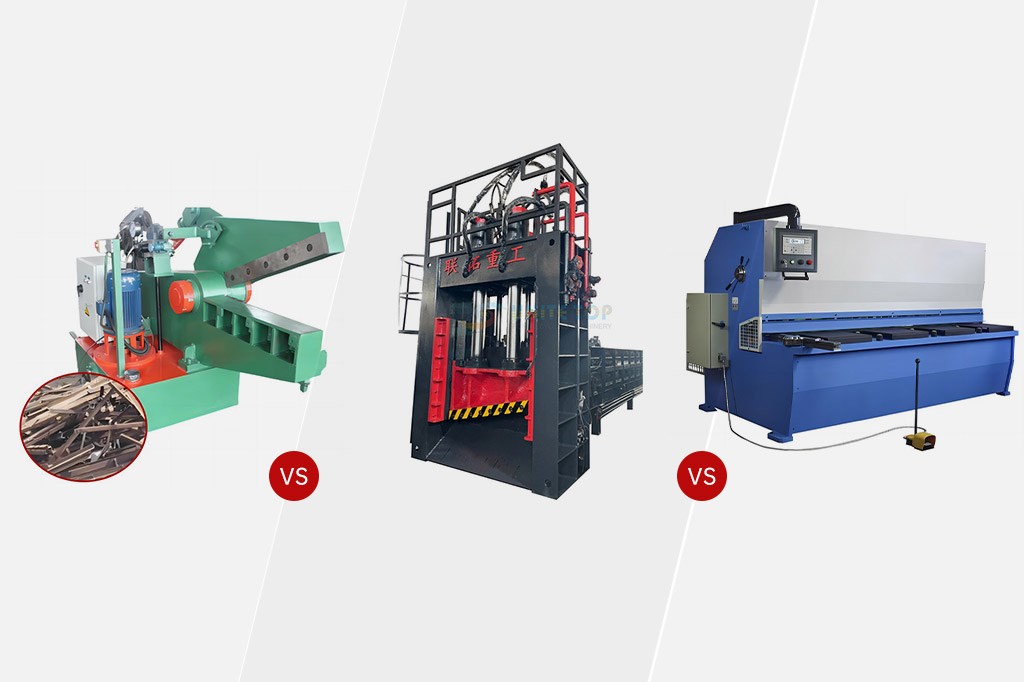

Three of the most popular scrap metal recycling machines are the Gantry Shear, Alligator Shear, and Guillotine Shear. Each machine has unique advantages, and understanding their differences can help you select the best one for your recycling operation.

This article examines the features, advantages, and drawbacks of each machine, assisting you in making an informed decision.

A Quick Comparison

| Feature | Gantry Shear | Alligator Shear | Guillotine Shear |

| Primary Use | Cutting large, heavy scrap metal like beams, pipes | Cutting smaller scrap metal pieces like rods, bars | Cutting metal sheets, plates, and thicker pieces |

| Cutting Mechanism | Vertical blade moves downwards | Hinged blade closes like an alligator’s jaw | Straight blade that moves vertically |

| Portability | Typically stationary | Often mobile, can be moved on-site | Usually stationary, larger footprint |

| Cutting Capacity | High | Moderate | High |

| Precision | Medium | Low | High |

| Efficiency | Efficient for large volumes of heavy scrap | Quick for smaller and medium scrap | Efficient for cutting metal sheets and plates |

| Cost | High | Moderate | High |

| Best Application | Industrial scrap yards, heavy-duty cutting | Recycling facilities, smaller operations | Fabrication shops, industrial scrap processing |

| Maintenance | High | Low | High |

| Mobility | Limited mobility, mostly fixed in place | Highly mobile, can be used in different locations | Limited mobility, usually fixed in place |

The above table is a comparison of the characteristics of the three types of Metal Shear Machines. The following is a detailed introduction to the advantages and disadvantages of each product.

Gantry Shear

A powerful machine for scrap metal recycling, the gantry shear features a large horizontal cutting blade operated by a hydraulic gantry. It is ideal for processing bulky, heavy scrap materials like beams, pipes, and structural steel, delivering precise cuts and high throughput for large-scale recycling operations.

|

Pros |

Cons |

|

|

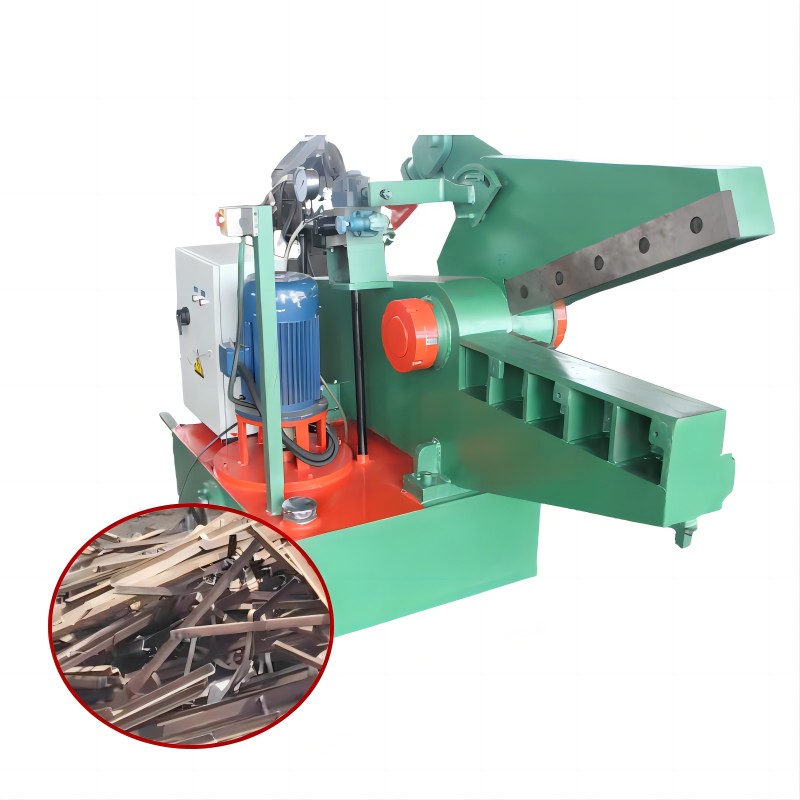

Alligator Shear

The alligator shear is a versatile and compact hydraulic metal-cutting machine with a scissor-like blade, perfect for cutting smaller metal pieces, bars, and tubing. It is commonly used in scrap yards for quick, efficient processing of medium-sized scrap metal, offering both portability and ease of use.

|

Pros |

Cons |

|

|

Guillotine Shear

A guillotine shear uses a vertical, downward-pressing blade to cut large metal sheets, plates, and oversized scrap metal. It provides precise, straight cuts for high-volume processing, making it a suitable choice for recycling operations dealing with flat metal materials and thick metal sheets.

|

Pros |

Cons |

|

|

Factors to Consider When Choosing a Shear

When selecting the best shear for your scrap metal recycling needs, it’s important to consider several factors that will influence your decision:

Material Type and Size

The type and size of scrap metal are crucial factors. For large, bulky materials like beams and pipes, the Gantry Shear offers superior power. The Alligator Shear is better suited for smaller items like rods and bars. If cutting flat metal sheets or plates, the Guillotine Shear provides precise, clean cuts.

Volume of Material

The volume of scrap metal dictates shear capacity. Large-scale operations benefit from the Gantry Shear’s efficiency in handling significant volumes. Smaller scrap yards can rely on the versatile Alligator Shear, while flat metal operations will find the Guillotine Shear ideal for high-volume precision cutting.

Portability

If your recycling operation requires mobility, such as moving the machine within the scrap yard or transporting it to different locations, the Alligator Shear’s portability is a key advantage. Both the Gantry Shear and Guillotine Shear are stationary machines, so they are best suited for fixed-site operations.

Space and Infrastructure

Facility space is a key consideration. The large Gantry Shear requires significant floor space and infrastructure due to its size and complex hydraulic system. On the other hand, the compact Alligator Shear is well-suited for smaller spaces, making it perfect for operations with limited space. The Guillotine Shear also needs space but is more specialized for facilities focused on processing flat metal.

Upkeep and Operating Expenses

Upkeep and operational costs vary. The Gantry Shear, though powerful, requires frequent upkeep and higher costs. The simpler Alligator Shear is more cost-effective and minimizes downtime. The Guillotine Shear offers moderate maintenance with the advantage of precision cutting, and balancing between the two.

Budget

Budget plays a key role in choosing a shear. The Gantry Shear requires a significant investment for large-scale operations. The more affordable Alligator Shear suits smaller businesses, while the Guillotine Shear offers specialized cutting, with costs depending on size and features.

Conclusion

Selecting the right shear for your scrap metal recycling operation is crucial for improving efficiency, reducing costs, and maximizing profitability. The Gantry Shear, Alligator Shear, and Guillotine Shear each offer distinct advantages, and understanding these differences will help you make an informed decision.

By considering factors such as material type, volume, portability, space, maintenance, and budget, you can choose the best machine for your specific needs and ensure a successful recycling operation.